Measuring methods

Table of contents

Why are material measurements so important?

The material measurements of the building physics research and development laboratory are: Precise measurements of specific characteristic values of materials, in particular building materials, e.g.

- Brick,

- Concrete,

- Wood,

- Plaster,

- Insulating materials,

- Paints,

- *

and also serve as the basis for energy-related renovation concepts, e.g. for insulation concepts or drying measures, etc. With the help of (hygro)thermal simulation, we accompany you on the way to an individual concept.

Standard Measuring methods and evaluation

Bulk density ρ

Determination of bulk density[6] by exact gravimetric measurement. Gravimetry is a quantitative analysis method based on the weighing of substance quantities. Ions or molecules are precipitated, filtered, washed and dried. The quotient of the mass of the dried sample and its volume determined via the geometry is determined.

Porosity Φ

The porosity is commissioned if required.

Water absorption coefficient Aw (according to EN ISO 15148[1])

The water absorption coefficient[1] is determined via the change in mass of a test specimen. The change in mass results from water absorption by capillary suction. To enable capillary suction[7], only the surface of the test specimen to be tested is brought into direct contact with liquid water.

The test specimens are placed in an underbody suspension of a balance above a water bath. By adjusting the system, only the test surface is brought into contact with the water surface.

Thermal conductivity λ and heat capacity cp

There are two different methods for measuring thermal conductivity[5] and/or volumetric thermal conductivity:

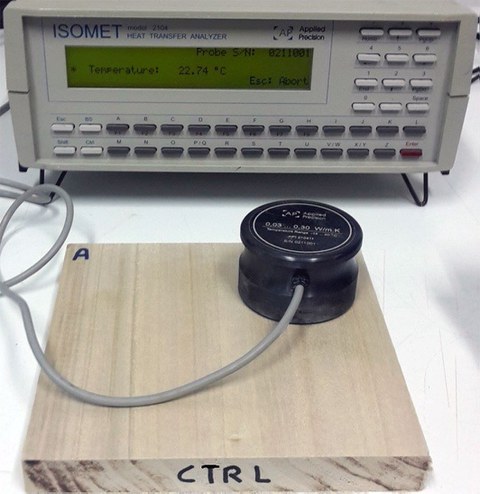

Heat-Pulse-Method

In this method, a defined heat pulse is induced on a material surface. The temperature curve is then determined over time. The thermal conductivity and heat capacity[2] are then calculated from this.

For this storage, flat surfaces are produced on several test specimens on which the test head of the measuring device can be positioned.

(Water) vapor diffusion resistance (number) μ (according to DIN EN ISO 12572[3])

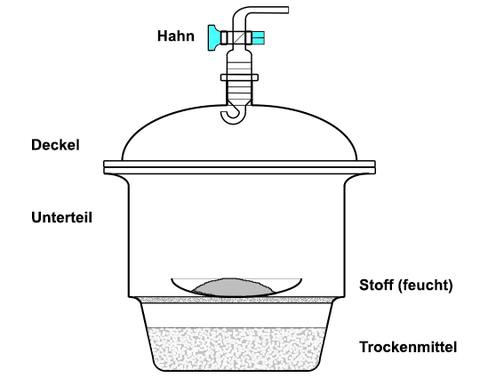

In an isothermal overall system, a constant vapor flow is generated perpendicular to the surface of the test specimen to be examined. This is achieved by two different but constant air humidities on the opposite sides. The humidity gradient generated in this way leads to an equalizing effect in the specimen perpendicular to the surface, the vapour flow. Since the boundary conditions for the vapor flow are constant, it will be constant after a longer transient phase. This condition is to be achieved. The test specimen is glued airtight into the opening of a lid so that the surface to be examined faces inwards.

The container to this lid is filled halfway with a salt solution that provides the desired humidity on this side of the sample.

The vessel is sealed airtight by the lid with the glued-in test specimen; this structure is called a cup. The room air humidity on the outside of the test specimen is generated via a climate chamber in which the cups are placed. The different room air humidities now cause the vapor flow through the test specimen and thus a change in the weight of the cup. This change in weight of the cups is then measured over time. The methods are divided into dry cup and wet cup. In the dry cup, humidity levels of around 0-5% prevail in the climate chamber and around 32% in the cup itself. With the wet cup, humidity levels of around 65 % prevail in the climate chamber and around 95 % in the cup. This means that the moisture flow always goes from the inside of the cup into the climate chamber.

Practical moisture content at 80% r.h.

The practical moisture content[4] is a typical parameter for the moisture load of building materials. It is used to select and adjust reference materials from the Delphin database. The moisture content is determined by storing a material in a desiccator at a humidity of, for example, 80 %.

An equilibrium moisture content is established in the building material. The difference in mass compared to the dry test specimen can then be used to determine the volume of water in the building material.

Extended laboratory examinations

In addition to the tests already listed, further tests and analyses can be carried out in the laboratory. This enables a more thorough evaluation of samples and materials under controlled conditions. The additional services help to increase the accuracy of the results and enable well-founded conclusions to be drawn and suitable measures to be recommended.

Drying experiment

Determining the drying behavior of a saturated material under constant ambient conditions results in a precise time curve and the mechanisms of the drying process can be analyzed. Parameters such as moisture content, temperature and humidity are controlled in order to obtain accurate data. These investigations provide important insights into the reactivity of materials used in different areas.

Capillary condensation test

Test specifically for open-pored insulation materials by measuring the moisture absorption over time and the spatial distribution of condensation. The materials are laterally sealed and insulated. Contact with a cooling plate creates a temperature gradient that transports moisture from the warm, humid laboratory climate to the cold back of the insulating material. The amount and distribution of moisture enable the quantification of liquid transport under these conditions.

Material functions for simulation software

To create the material function, the results of the determination of liquid water conductivity and vapor conductivity as a function of moisture are taken into account. The simulation is automatically calibrated based on the laboratory experiments using an optimization algorithm of inverse modelling. This enables precise adaptation of the simulation parameters to the real experimental conditions and contributes to improved accuracy and predictive power of the models.

| Parameter/ Test | COND[8] | DELPHIN[8] |

|---|---|---|

| Thermal conductivity | X | X |

| Moisture storage | X | X |

| Water absorption | X | X |

| Water vapor diffusion resistance | X | X |

| Drying experiment | X | |

| Capillary condensation test | X |

Citation

- [1] DIN EN ISO 15148 Thermal and moisture performance of building materials and products - Determination of the water absorption coefficient by partial immersion, December 2018

- [2] DIN EN ISO 10456 Building materials and building products, thermal and moisture properties, DIN Deutsches Institut für Normung e.V., Berlin, May 2010

- [3] DIN EN ISO 12572 Thermal and moisture performance of building materials and products - Determination of water vapor permeability - Method using a test vessel, May 2017

- [4] DIN 4108-3 Thermal insulation and energy conservation in buildings - Part 3: Climate-related moisture protection - Requirements, calculation methods and guidance for design and construction, October 2018

- [5] DIN EN 1745 Masonry and masonry products - Methods for the determination of thermal insulation properties, October 2020

- [6] DIN 4108 Thermal insulation and energy conservation in buildings - Part 4: Thermal and moisture insulation design values, DIN Deutsches Institut für Normung e.V., Berlin, March 2017

- [7] DIN EN ISO 12570 Thermal and moisture behavior of building materials and building products - Determination of moisture content by drying at elevated temperature, July 2018

- [8] www.bauklimatik-software.de