Feb 24, 2023

Newest publication: J. Dostál & S. Heidinger in MDPI processes

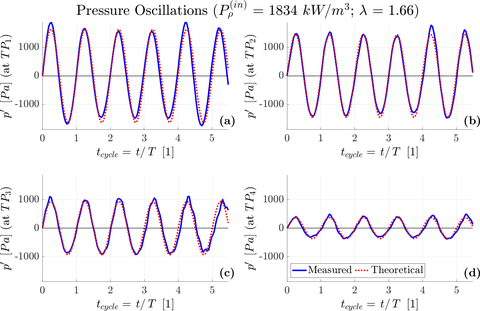

Figure: Oscillating pressure part for one specific operation point - comparison of the actually measured data with the theoretical oscillations following an ideal sine function. Each subplot displays the pressure at one location along the tailpipe.

Our latest publication was published on February 1st, 2023, in the journal MDPI processes and is available online here. It is entitled Effects of Fuel Input on Pulsation Reactor Behavior - An Experimental Study. The authors, Jakub Dostál and Stefan Heidinger, are both expected to complete their dissertations within the 3rd Research Training Group soon. Both worked in subproject A2 Theoretical and experimental investigation of process boundary conditions in pulsating flows for the production of novel oxidation catalysts.

What is the publication about? Material treatment in pulsation reactors (PR) brings the possibility of synthesizing powdery products with advantageous properties, such as nanoparticle sizes and high specific surface areas, at an industrial scale. The extraordinary material properties can be ascribed to special process parameters in a PR, primarily the periodically varying conditions and the consequently enhanced heat and mass transfer between the medium and the particles of the material. Understanding the connections between the PR operation parameters, such as fuel and air intake or PR geometry, and the resulting process parameters (temperature distribution, flow velocity and pressure field, and frequency of the pulsations) is essential to enabling a controllable treatment process. Despite the long history of pulsation reactor technology, many connections and dependencies remain unclear. Thus, the influence of the fuel (and air) supply on the pulsation reactor behavior is experimentally examined in the study. The investigated PR characteristics and process parameters are primarily those that have an impact on the heat and mass transfer (i.e., the temperature distribution, flow velocity, and pressure field), and frequency of the pulsations. In addition to these, the harmonic distortion of the oscillations and the heat losses are evaluated.