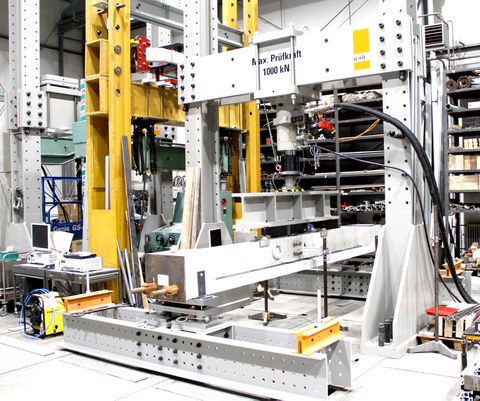

Hydraulische Prüfzylinderanlage

Prüfzylinderanlage im Otto-Mohr-Laboratorium

Die hydraulische Prüfzylinderanlage ist eines der Herzstücke im Otto-Mohr-Laboratorium und ist für anspruchsvolle statische und dynamische Prüfungen geeignet.

Durch ein direkt unter der Prüfanlage befindliches Aufspannfeld können Bauteile mit einer Länge von 1,50 m bis ca. 6 m und durch die variabel einstellbare Prüfraumhöhe auch bis zu 3 m hohe Bauteile getestet werden. Es stehen verschiedene Prüfportale sowie diverse, untereinander austauschbare Prüfzylinder mit unterschiedlichen Lastkapazitäten zur Verfügung. Die maximale statische Lasthöhe von bis zu 1 MN und dynamisch bis zu 600 kN erlauben Beanspruchungen im höheren Kraftbereich. Quasistatische kraft- oder weggeregelte Druck- und Biegeversuche dienen dabei vorrangig zur Ermittlung des Bruchverhaltens oder zur Bestimmung der maximalen Belastung und Dehnung von Werkstoffen und Bauteilen, wie beispielsweise Betonbalken, Decken- und Wandelementen. Neben der Möglichkeit zur statischen Prüfung können mit der Prüfzylinderanlage auch zyklische Versuche durchgeführt werden. Dabei werden die dynamischen Kräfte über einen Gleichlaufzylinder aufgebracht, welcher sich auf dem Querhaupt befindet. Die Ölversorgung erfolgt durch das bestehende Zentralhydraulikaggregat. Die Prüffrequenz im dynamischen Prüfbereich ist abhängig von der maximal gewünschten Amplitude. Der maximale Hub der Zylinder ist auf 250 mm begrenzt.

Ein extern zur Verfügung stehendes Mehrkanalmesssystem ermöglicht die Messdatenerfassung auch über längere Prüfzeiträume. Ebenso können photogrammetrische Messaufgaben durch die offene Bauweise gelöst werden. Eine im Jahr 2022 erneuerte Maschinensteuerung ermöglicht nun eine noch akkuratere Bedienbarkeit der Kraft- oder Wegregelung.

| Technische Informationen | Technical information | ||

| Maximale statische Prüflast (Druck) | Maximum static test load (compression) | 1 MN | |

| Maximale zyklische Prüflast | Maximum cyclic test load | 600 kN | |

| Maximaler Kolbenweg | Maximum cylinder lift | 250 mm | |

| Prüfraumbreite | Work space width | 2,50 m | |

| Prüfraumhöhe | Work space clearance | ≤ 3,00 m | |