Modeling and simulation of wood forming processes

Thermo-hygro-mechanical processes for densification and forming of wood:

Continuum-mechanical material modeling and structural simulation

Research topics

- Phenomenological description of constitutive characteristics of the wood forming process

- Development of realistic, macroscopic, numerical tool for modeling wood by using an invariant-based anisotropic elasto-plastic material model for wood at large deformations

- Consideration of the influence of temperature and moisture, e.g. by a thermal hygroscopic finite surface element and constitutive formulations

- Parameter identification by comparison of experiments and simulations

- Industry- and application-related simulation of structures made from formed wood by means of the finite element method

Funding

Deutsche Forschungsgemeinschaft (DFG)

In collaboration with

- Professur für Ingenieurholzbau und baukonstruktives Entwerfen, Fakultät Bauingenieurwesen, TU Dresden

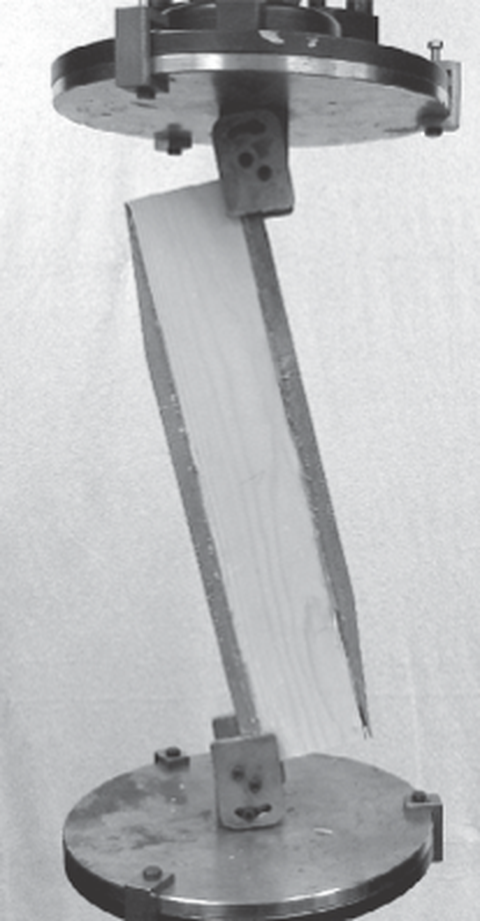

Experimental setup of shear test at spruce wood

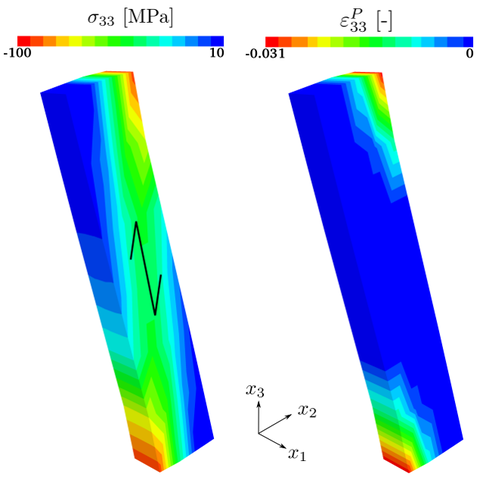

Simulation results of shear test at spruce wood, stresses (left) and plastic deformation (right)

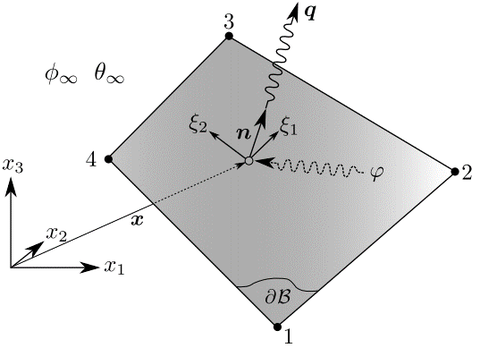

Schematical depiction of a finite surface element for modeling thermal convection and moisture in-flow and out-flow

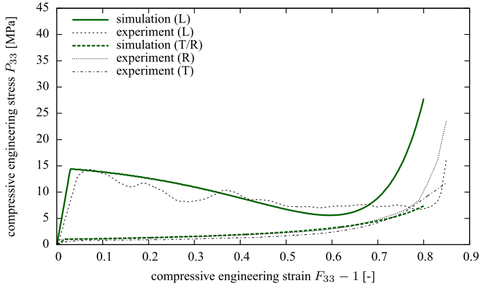

Numerical comparison of simulation results and experimental measurements at uniaxial compression tests with different fiber orientations at balsa wood

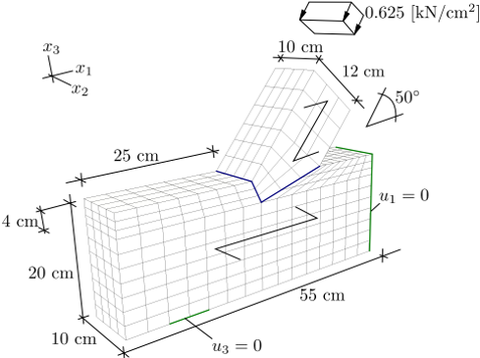

Geometry, discretization and boundary conditions for the simulation of a face staggered joint

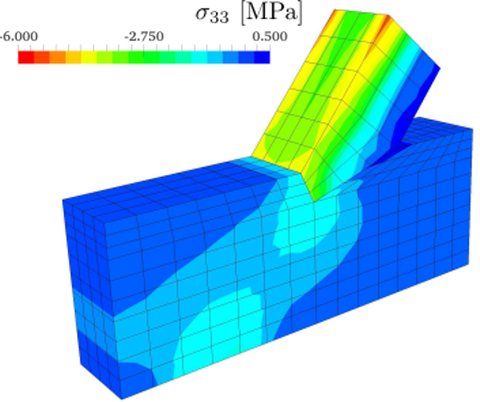

Stress distribution as a numerical result of the simulation of a face staggered joint