Vehicle Test Centre

The Vehicle Testing Centre (FVZ) at the Institute of Automobile Engineering Dresden - IAD of the TU Dresden

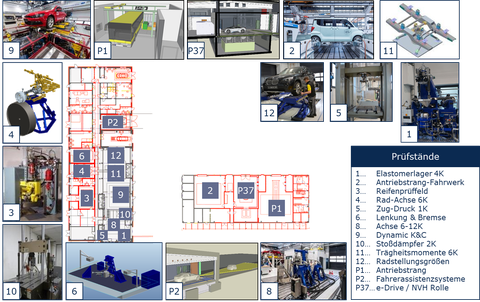

Prüfstandsübersicht

The Vehicle Test Centre of the TU Dresden (FVZ) is a globally unique instrument for basic to applied research in vehicle technology at universities. In addition to new simulation methods, new experimental methods are being developed by the Chairs of Automobile Engineering and Vehicle Mechatronics. At the FVZ, these methods are implemented on existing test benches and in the form of new test benches. A particular focus of research is on methods for digitization in vehicle development and virtual testing.

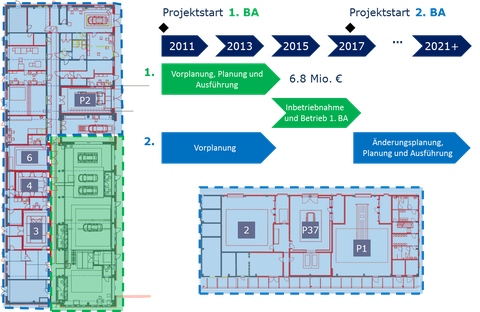

The project Vehicle Test Centre is divided into three construction phases.

- Construction phase: Building 127 Hohe Halle - Parametrierstraße, 2013-2015

- Construction phase: Building 125 / 127 Completion site August-Bebel-Str. 32, 2017-2023

- Section: Simulator building

Bauabschnitte

After the approval of the demand for testing and experimental facilities for research and teaching requested by the Chairs of Automobile Engineering and Vehicle Mechatronics in 2011, the basic determination and preliminary planning of the first and second construction phases were carried out. In addition, the basic evaluation for the final construction phase 3 could be started. In 2013, after approval of the draft planning of the first and second construction phases, the Free State of Saxony was able to acquire a suitable site of approx. 1.4 hectares in August-Bebel Straße 32 in Dresden and continue planning with the implementation planning of the first construction phase "Hohe Halle" (green). The first construction phase in December 2014 marked the completion of the first part of the largest infrastructural expansion project ever undertaken by the Institute of Automobile Engineering (IAD) in its more than 100-year history.

A special feature of this project is the simultaneous development of test benches and buildings. In this project, a novel simulation-based procedure was developed, which allows a completely virtual development of both areas in a maturity-dependent detail depth up to the execution planning.

1st construction phase: Building 127 Hohe Halle - Parametrierstraße

The first construction phase took place from 09/2013 to 12/2014, so that after completion in December 2014, the installation of the seven test benches completed by then could already begin on 04 January 2015. The total construction costs of the first construction phase amounted to EUR 6.8 million. Within this construction phase, in addition to the development of the site and the redesign of the high hall area, an efficient electrical supply, central ventilation and cooling systems, a central hydraulic and compressed air supply and two individual vibration foundations (340t and 140t) with level control for decoupling the test benches were implemented.

Gebäude 127 Hohe Halle

With the completion of commissioning, the following test facilities have been available since March 2016:

- Servo-hydraulic test bench with lateral force device [MTS]: Static and dynamic characterization of shock absorbers, elastomer bearings, etc.

- Tensile and compression test rig [Zwick/Roell]: Static load tests, characterization, calibration DMS applications

- Servo-hydraulic axle test bench [Hardware in-house development / control MTS]: Static and dynamic characterization of vehicle axles from wheel carrier, load tests

- Dynamic Kinematics & Compliance Test Stand [MTS SMS]: Static and dynamic determination of axle kinematics and elastokinematics of vehicle axles in the complete vehicle

- Vehicle pendulum frame [in-house development]: Determination of centre of gravity and mass inertia parameters for complete vehicles

- Wheel alignment [Beissbarth]: Parameter determination of the axle geometry

In May 2017, the previous measuring and testing device for elastomer bearings was replaced by a state-of-the-art 4-component test rig.

- Servo-hydraulic elastomeric bearing test rig with thermal chamber [INOVA]: Static and dynamic characterization of elastomeric bearings in 4 degrees of freedom with thermal load, operating load tracking tests, load iteration

The test facilities that have already been completed are arranged in such a way that they can remain fully operational during the construction phase of the second construction phase.

Gebäude 127 Hohe Halle von hinten

2nd construction phase: Building 125 / 127 Completion of the August-Bebel-Str. 32

In June 2017 the Saxon Real Estate and Construction Management together with the TU Dresden started with the implementation planning for the second construction phase. The remaining test facilities of the Chairs of Automotive Mechatronics and Automotive Technology will be installed and commissioned in both test buildings. The construction phase for the second construction phase will begin in June 2018 with the refurbishment of the drainage systems and will be completed on schedule in the second quarter of 2022. After commissioning, the following test facilities will then be available:

Automobile Engineering

- Combined chassis-drive train test rig [HORIBA] This test bench will be available in a reduced form in Jantebau as early as August 2018.

- Highly dynamic tire test field [in-house development] dynamic parameter identification, characterization, load tests, rolling resistance on tyres

- Wheel-axle test rig [in-house development] Real driving manoeuvre simulation on vehicle axles, dynamic parameter identification, characterization and load tests on wheel suspensions with wheels up to complete axles

- Servo-hydraulic / electromechanical test bench for steering systems [in-house development] Static and dynamic characterization of steering systems, load tests

Vehicle Mechatronics

- 4-Motor Vehicle-in-the-Loop test bay Static and dynamic characterization of drive trains in the vehicle, load tests, operating strategy

- Driver assistance system test bench Functional investigation of automated driving functions, assistance systems and control systems

- eDrive roller dynamometer Multifunctional test bench for performance measurement, operating strategy and interior noise investigations in cooperation with automotive technology

- Various function rooms for examinations of components and the on-board network

If you have any questions about the FVZ and the planning status, please contact the planning team at the Chair of Automotive Engineering:

This project is co-financed by tax revenues on the basis of the budget approved by members of the Saxon state parliament.