Nov 19, 2024

New study on Distributed Flow Shop Scheduling published in EJOR

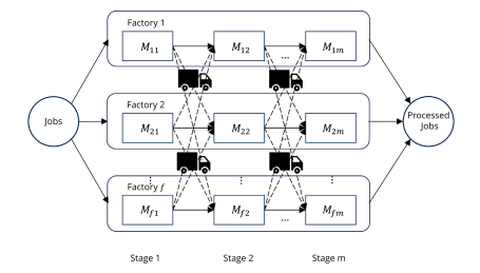

Large manufacturing companies often manage a network of multiple factories, creating a distributed flow shop scheduling problem for flowline manufacturing processes.

This problem involves assigning jobs to one of several distributed factories, each equipped with identical flow shops, and completing the jobs within their designated factory. We expand upon the traditional distributed flow shop scheduling problem by incorporating the transportation of intermediate goods between factories. This transportation can occur after each machine, with shipping times dependent on the distance between the origin and destination factories, potentially delaying further processing.

Our objective is to minimize the makespan across all factories. We introduce an iterated greedy search procedure specifically designed for distributed flow shop scheduling with inter-factory transportation. Based on a graph representation, a speed-up procedure is developed to improve the algorithms search ability. Through computational studies, we demonstrate the effectiveness and efficiency of our proposed algorithm, and provide insights into the benefits of transportation.

Our findings indicate that incorporating transportation enhances machine utilization across factories by alleviating bottlenecks, ultimately improving overall efficiency and reducing makespan. Besides, we are able to quantify the trade-off between transport times and the benefits of inter-factory transportation.

Becker, T., Neufeld, J. & Buscher, U. (2024). European Journal of Operational Research. https://doi.org/10.1016/j.ejor.2024.10.026