Forschungsfelder

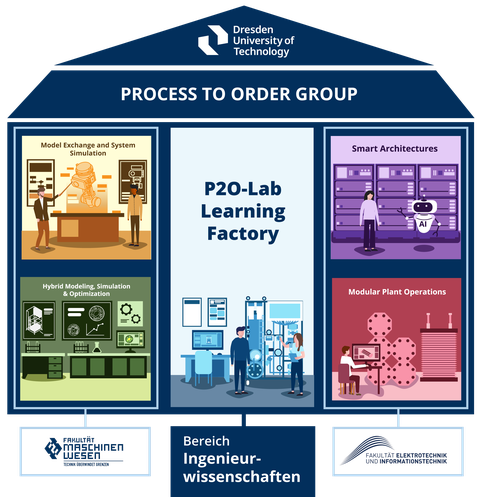

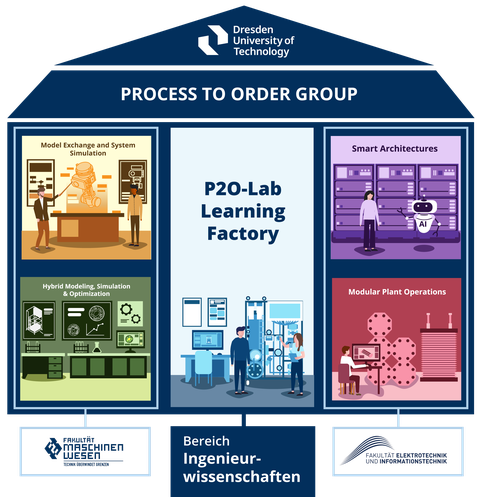

P2O-Group Strukturübersicht

Eine Übersicht über die Forschungsgebiete der Process-to-Order Group ist hier zu finden: Forschungsfelder

P2O-Group Strukturübersicht

Eine Übersicht über die Forschungsgebiete der Process-to-Order Group ist hier zu finden: Forschungsfelder