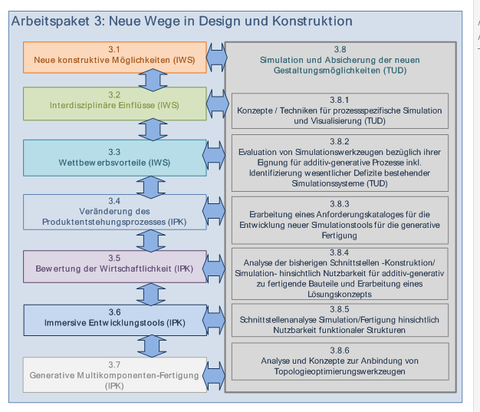

Agent-3D_Basis: Framework conditions for additive-generative manufacturing, sub-project: Simulation and validation of new design options

| Runtime | 01.12.2015 – 30.11.2018 |

| Funding | BMBF |

| Project lead | Dr.-Ing. habil. Christine Schöne (former staff member) |

| Project staff | Dr.-Ing. Philipp Sembdner |

| Partners | Fraunhofer-Gesellschaft zur Förderung angewandter Forschung e.V. München, verschiedene Institute |

| Technische Universität Berlin, Institut für Werkzeugmaschinen und Fabrikbetrieb, IWF | |

| Technische Universität Dresden, Institut für Werkstoffwissenschaft |

Motivation

- Additive-generative manufacturing processes put the right material in the right place without tools, with high precision, flexibility, resource and economy efficiency , without significant rework.

- with integrated intelligence enable products with radically new functionalities and property profiles that generate high demand worldwide and open up new markets.

- Individualised single items and series products in high quantities are developed and manufactured in predominantly virtualised process chains. Product manufacturing is exclusively on-demand and can take place both centrally and decentrally.

- Germany is becoming the leading provider for additive-generative manufacturing across the board. Companies from the new federal states are setting the pace for the development into a key technology along the entire value chain.

Objective

Objective

Project content

In the sub-project of the chair, methods of simulation and validation of the new design options are to be investigated.