Parameterisation of individual knee implants for planning and production using EBM (sub-project)

| Runtime | 01.10.2017 – 30.09.2020 |

| Overall project | Expertensystem für das Design und die Fertigung von Endoprothesen mittels Electron Beam Melting (EXPERTEB) |

| Funding |

BMBF |

| Project staff | Dr.-Ing. Philipp Sembdner |

| Partners |

Dornheim Medical Images GmbH |

|

Engelke Engineering Art GmbH |

|

|

FIT AG |

|

|

Institut für Bioprozess- und Analysenmesstechnik (IBA, Heiligenstadt) |

|

|

Universitätsklinikum Freiburg, Klinik für Orthopädie und Unfallchirurgie |

Motivation

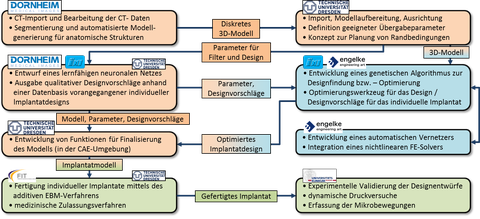

The technology project "Expert system for the design and manufacture of endoprostheses using Electron Beam Melting (EBM) (EXPERTEB)" aims at both automation and improved user support to accelerate and simplify the manufacturing process for patient-specific endoprostheses, also as a prerequisite for the additionally targeted model optimisation. Individual endoprostheses have a significant advantage because their design is specifically adapted to the patient's anatomy. This means that the artificial joint and the patient's bone already fit together perfectly before the operation. As a result, the doctor has to remove much less bone material during the operation than with traditional endoprostheses / implants. This is particularly important for younger patients, as with a very long durability of over 20 years, more of the patient's own bone material is available for a possible replacement operation. Furthermore, the new imaging procedures and manufacturing methods enable exact geometries that do not require any compromises in contrast to the available regular implants. The design and development process for patient-specific prostheses or implants is to be automated by means of modern, computer-assisted routines and algorithms.

Objective

- Automation of currently predominantly manual processes, such as CAD generation (with segmentation and reverse engineering), numerical modelling (with meshing as well as definition of boundary conditions).

- Further optimisation of the individual implant design with regard to biomechanical properties of the implant or implant composite to ensure an optimal clinical fitting

- Development of an automatic process (expert system) for designing an individual knee prosthesis (generation of the digital model for additive manufacturing) on the basis of individual CT/MRI data and use of knowledge-based and intelligent processes to ensure product quality and shorten manual efforts and thus also development time

Project content

Video on the project completion

Video zum Abschluss des EXPERTEB-Projekts