Design of a deep-drawing tool for the production of covers at HARMONA Akkordeon GmbH

| Runtime | 01.08.2011 - 31.07.2013 |

| Funding | Funding program „Zentrales Innovationsprogramm Mittelstand“ of the Bundesministeriums für Wirtschaft und Technologie (BMWi). |

| Project staff | Dipl.-Ing. Dirk Hofmann (former staff member) |

| Partner | HARMONA Akkordeon GmbH |

Here you can download the article on this topic (published in VDI Konstruktion 10-2014).

Objectives

The focus of the task was the design of a deep-drawing tool taking traditional manufacturing methods into account.

The starting point were the individual parts and their tools, which were recorded and reprocessed with the help of the reverse engineering process chain. This served as the basis for the redesign and construction.

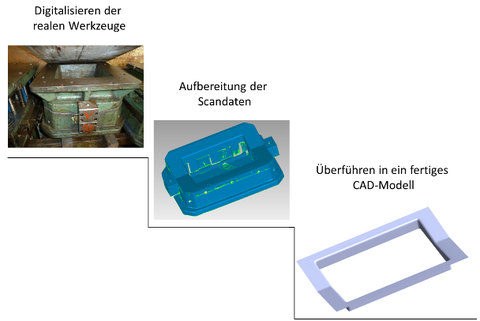

3 Phases of 3D digitising and preparation using the example of a die for deep drawing

Project content

- 3D digitising and reconditioning of the individual parts and their tools at various stages of production

- Comparison of workpieces and tools by analysing the material (drawing gap, flow behaviour, etc.)

- Investigation of the manufacturing parameters by means of 2D, 3D analysis, screening of the raw sheets and deep-drawing simulation

- Testing and analysis of alternative materials for individual parts and also for tools

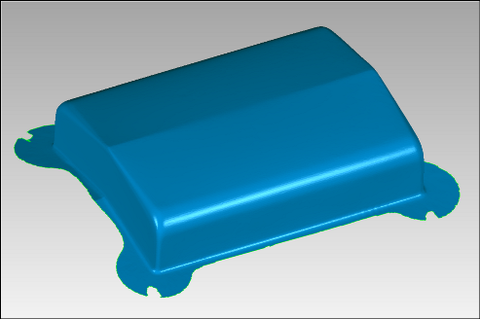

Scan data of a double bonnet

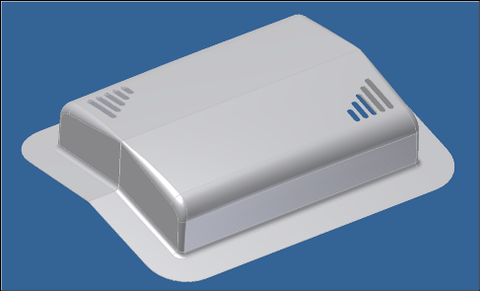

Parametric CAD model of a double bonnet

Implementation:

- Using the results - determining the dimensions for the individual variants

- Redesign of the soft tops - construction of a parametric CAD model for

- simpler derivation of the variants

- better planning of further production steps (CAD/NC) - Construction and testing of various modular systems