Design, calculation and manufacture of complex geometric structures by means of laser beam melting

| Runtime | 01.08.2016 – 31.07.2018 |

| Funding | DFG |

| Project lead | Dr.-Ing. habil. Christine Schöne (former staff member) |

| Project staff | Dipl.-Ing. Peter Koch |

| Partners | Fraunhofer-Institut für Werkzeugmaschinen und Umformtechnik |

Motivation

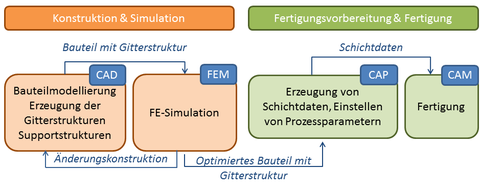

The potential of generative manufacturing for free design has not been exploited so far due to a lack of suitable design guidelines. In addition, there is a lack of suitable tools in the CAD environment that could support a design. Intricate structures, also referred to as complex geometric structures inside the components, have so far only been generated close to the machine. This means that component design in terms of strength, deformation and thermal behaviour is not carried out, only roughly or at a very late stage in the development process. This deficit is to be eliminated through the design and implementation of construction tools and an interface concept up to production for complex geometric structures.

Objective

Project content

- Design of construction tools for CAD systems for modelling complex geometric structures

- Development of an interface concept / data model for the continuous and consistent transfer of data within the product development process

- Development of a concept for calculating the structures in terms of mechanical properties and feedback to the design in order to be able to make changes to complex geometric structures in CAD,

- Verification of the portability of the data to the production line

- Mechanical testing of manufactured structures and determination of mechanical parameters