RessFAST Increasing material efficiency through resource-efficient production for components made of aluminium, steel, titanium

| Runtime | 01.02.2016 – 31.01.2019 |

| Funding | BMBF |

| Project lead | Dr.-Ing. habil. Christine Schöne (ehem. Mitarbeiterin) |

| Project staff |

Dipl.-Ing. Michael Süß (former staff member) |

| Dipl.-Ing. Dirk Hofman (former staff member) | |

| Partners | KSB Aktiengesellschaft |

| Airbus Defence and Space GmbH | |

| H&E Produktentwicklung GmbH | |

| TLS Technik GmbH & Co. Spezialpulver KG (TLS) | |

| Fraunhofer-Institut IFAM, Institutsteil Dresden | |

| Steinbeis-Hochschule Berlin GmbH |

Motivation

The efficient use of existing resources in production plays a decisive role in times of increasing resource scarcity. According to a study on the relevance of resource efficiency, just under half of the companies surveyed conduct targeted research and development to increase it. Energy and material efficiency were identified as the most important topics. Therefore, the proposed project aims to achieve a more efficient use of natural resources for selected industrially very important materials by increasing the specific material yield.

Objectives

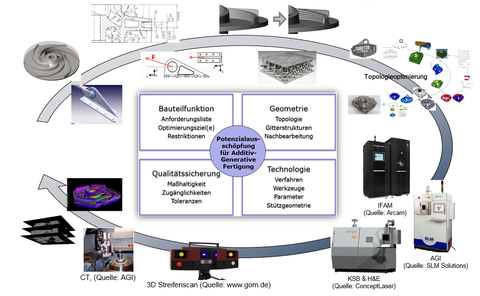

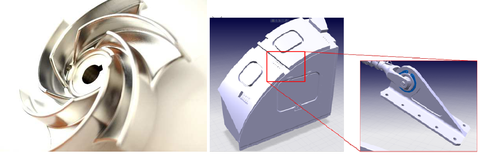

Due to the high degree of design freedom, generative processes allow completely new paths in design with lightweight structures, bionic concepts or integrated functionality that would not be possible with subtractive machining techniques or only at disproportionately high costs. This results in completely different possibilities for resource-saving design than previously possible. In the planned project, the focus will be on topology optimisation with the aim of reducing the use of materials while simultaneously fulfilling the specified load cases.

Project content

The entire value chain, from powder production and evaluation to the generative production of the components, is run through on the basis of specified components from the companies.