Functional model steam engine

| Project Staff: | Dr.-Ing. Wolfgang Steger Dipl.-Ing. Erik Steindecker (former staff member) Dr.-Ing. Dirk Petermann (former staff member) Christian Schulz (Student) a.o. |

| Partner: | Verkehrsmuseum Dresden |

Until the first third of the 20th century, steam engines were of great importance as driving machines. In museums and technical monuments, they exert a strong attraction and fascination as exhibits. Although the basic functioning and construction of steam engines are common knowledge for the technically interested, functional and constructive details, for example of the control system, are hardly known to this extent.

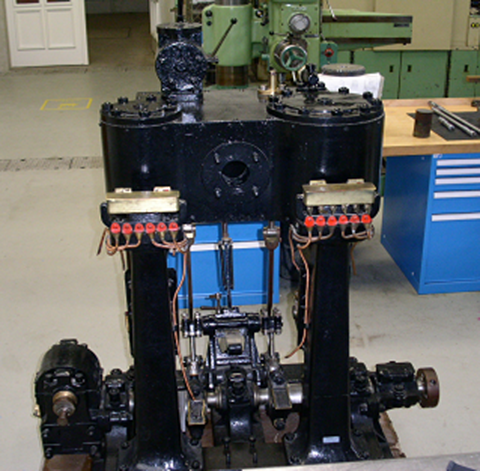

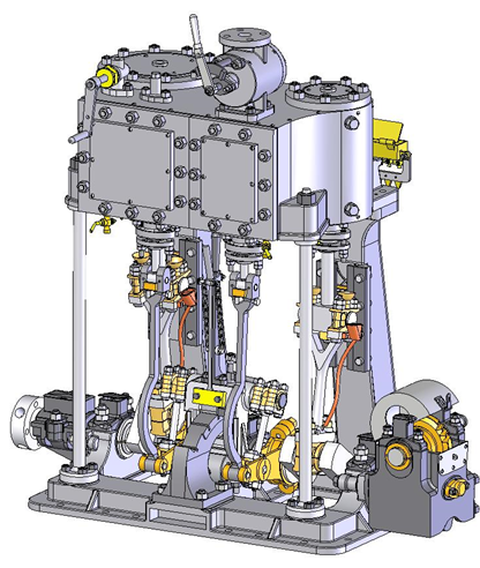

A ship's steam engine was converted into an interactive functional model for the Verkerhsmuseum Dresden. Since it is impossible to operate the engine in the museum for technical and economic reasons, it makes sense to illustrate the function with a VR representation (stereo projection with interactive animations/simulations). For the museum visitor, this creates impressions that the immobile model cannot generate. The subject of the project is a compound steam engine with two cylinders, which was built in 1927 as a ship steam engine by the "Dresdner Maschinenfabrik und Schiffswerft Übigau AG" with the construction number 1836. The engine was equipped with a Klug control system for forward/reverse motion and, according to the shipyard, generated 35 hp of propulsion power. It was intended for a Dresden ferry steamer, which was in service until about 1965, but converted to a diesel engine. The engine is in good condition and almost completely preserved. Some parts of the lubrication system and all components for steam supply and discharge are missing. The weight is about 750 kg. Since technical documentation is no longer available, the prerequisite for a VR representation is the creation of a 3D geometric model using the means of reverse engineering or/and by remodelling using a CAD system. In the present case, the steam engine was largely disassembled and measured. Subsequently, the 232 different parts were modelled and an assembly structure suitable for animation was created. In the case of the steam engine, the equations of motion of all moving parts were derived analytically from the data of the measurement and integrated into the animation as a DLL. Interactively one can:

- start the machine via steam inlet valve and regulate the speed

- control forward and reverse travel and cylinder filling via reversing lever

- hide/show different parts of the enclosure or display the machine as a section.

- look at the steam flow through the control and cylinder

In addition to the visualised states of the machine, typical steam engine sounds accompany the scenery. These are synchronised with the movement.