Jul 18, 2025

Doctoral student Konstantin Schmidt invites to a research presentation in the Jante Building

The RTG visiting the Jante Building (from left to right): Majid Ali, Jannik Amon, Christian Gutsche, Varun Gurugubelli, Markus Leyser, Ines Almeida, Konstantin Schmidt, Dr. Anna Martius, Sampath Weerappulli, Stefan Röher, Julia Erdmann, Lairana Lima Duarte, Shiyu Guo, and Marie Walstab.

On Thursday, 03.07.25, doctoral student Konstantin Schmidt (project H4: H2 and H2-based fuels in internal combustion engine applications) chose a special setting for his research presentation. Instead of holding it on the premises of the Boysen-TU Dresden-Research Training Group as usual, he invited the participants to the Jante Building at the Chair of Combustion Engineering and Drive Technology of Prof. Atzler, his project supervisor.

After the group had gathered in the inner courtyard, a poster presentation opened the technical part of the event. The focus was on the progress of the project over the past year, which mainly concentrated on the carbon-free energy source ammonia.

This was followed by the practical highlight of the day - a tour of the test benches. The tour began in an adjacent building, which houses two different test benches. First, a 1-cylinder research engine was inspected, which is being used as part of the project to investigate the use of methanol as a fuel. This is fully enclosed and can be cooled down to -25 °C in order to carry out realistic cold start tests. Another special feature is the special cylinder head, which uses endoscopes to enable the optical recording of combustion.

The 1-cylinder methanol engine on the test bench.

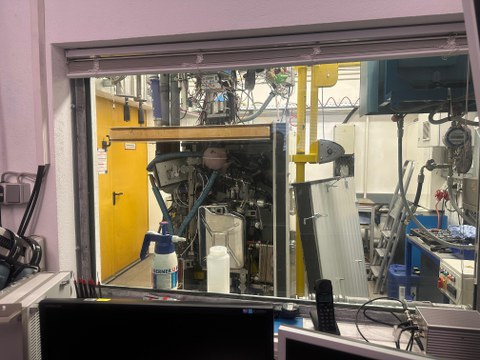

The constant volume chamber could then be viewed in the next room. This was used to carry out the previous fundamental investigations into the use of ammonia and hydrogen in the model test. In addition to extensive sensor technology, this test stand is also equipped with a high-speed camera system that allows detailed visualization of the combustion processes. In addition to premixed combustion, the behavior of direct fuel injection can also be investigated in a similar way to the diesel process.

Finally, the group made its way to the main building, which is equipped with a large number of other test benches. The range of systems available on site extends from 1-cylinder and motorcycle engines to a turbocharger test bench and a range extender in a simulated hybrid powertrain. A particular highlight here is the "altitude chamber", in which an altitude of up to 30,000 feet (approx. 9,100 m) can be simulated for aircraft engines. The air pressure can be reduced to 0.2 bar and the air temperature in the entire chamber can be lowered to -40 °C.

After an hour and a half of fascinating insights, the extraordinary presentation came to an end.