Selected major, completed Projcts/Scholarships since September 2017

Saltwater treatment for injection into hydraulic barriers

Funding Period: 01.01.2018 until 31.12.2020

Saxonian State Scholarship funded by the European Social Fund

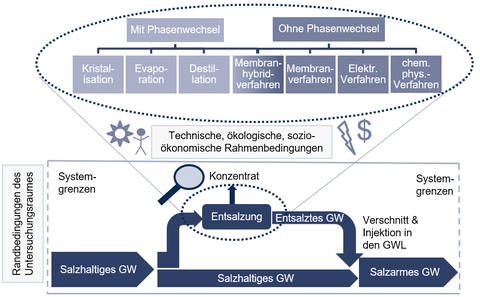

Within the scope of this work, suitable desalination techniques are examined within the use of mixed hydraulic barriers (MHB) to counteract seawater intrusion.

The work is divided into the following packages:

First, regions that are typically affected by saltwater intrusion are described and examined regarding to their basic conditions, as social structure, available energy and groundwater quality. Using this knowledge, various desalination techniques for the treatment of saline groundwater are investigated for respective boundary conditions. Therefore, the water recovery rate and the conductivity of the water were identified as crucial key factors for the evaluation of the desalination techniques.

The desalination is an industrial process that is chemically, energetically and operational complex. Within each desalination process, the saline water is separated into desalinated water (pure) and concentrated water (concentrate). According to Lattemann (2011), the multi stage flash distillation - with a market share of 50 % - and reverse osmosis - with a market share of 35 % - are the most often used seawater desalination techniques focused on drinking water treatment.

In multi stage flash distillation, saline water is evaporated at high temperatures under vacuum and collected as salt-free condensate in several stages. Reverse osmosis is the most often used desalination technique regarding not only the seawater desalination but also the whole desalination sector including the treatment of brackish water and wastewater. In this desalination technique, high pressure is used to press saline water through a semipermeable membrane overcoming the osmotic pressure. Due to this filter effect, only a few ions can pass the membrane. Advantages of reverse osmosis are the relatively low costs (0.5 – 1.0 US$/m³) and the possibility to use renewable energy, as solar power and wind energy. Disadvantages of reverse osmosis are the required pre-treatment, the high-maintenance, and the limited durability. Moreover, pressure-controlled or chemical cleaning steps have to be performed within the treatment due to scaling and fouling processes (Khawaji et al.; 2008, Lattemann, 2011; IEA-ETSAP & IRENA, 2012).

Further, membrane distillation is considered a relevant and low-maintenance desalination procedure (Winter et al., 2011). In this desalination technique, the temperature gradient is used as driving force, whereby only a vaporous phase can pass the hydrophobic membrane. The advantages of this technique are the high rejection rate, the low-maintenance and the low power demand if solar thermal energy or other directly available heat sources can be used to generate a high temperature gradient. Thereby, the membrane distillation can be used in decentralized areas as well (Koschikowski et al., 2003).

In order to guarantee an economic desalination at high volume flow rates, innovative technologies such as renewable energy e.g. solar energy, photovoltaics, wind energy or geothermal energy as well as the (re-) use of the concentrate are considered in this work.

Model concept for desalination of saline ground water [GW=ground water, GWL=aquifer] for injection in hydraulic barriers

Based on the literature research and the evaluation of suitable applications and implementation possibilities of selected desalination processes, a tool should be created which is able to calculate the quality and quantity of the desalinated groundwater by considering the boundary conditions of the research areas. Subsequently, the costs for desalination are calculated and integrated under the conditions integrated in the tool. With help of this tool, it should be possible to calculate the efficiency of a high salt rejection rate in combination with saline groundwater blending compared to a lower salt rejection. The model is to be validated on the basis of case studies.

Based on these results, application possibilities and boundaries of desalination techniques for injection into the aquifer to counteract saltwater intrusion are examined. The aim of this project is to answer the following questions:

- Which recovery rate and which rejection rate is economically and ecologically sensible regarding the desalination technique and where are the different variations applicable?

- What investment costs and operating costs can be expected?

- Which renewable sustainable energy can be used?

- How can the principles of a sustainable recycling economy be implemented by using the generated by-products?

Literature

- IEA-ETSAP& IRENA (2012). Water desalination using renewable energy. Technology Brief, International Energy Agency-Energy Technology Systems Analysis Programme & International Renewable Energy Agency. URL: http://www.irena.org/DocumentDownloads/Publications/Water_Desalination_Using_Renewable_Energy_ -_ Technology_Brief.pdf [letzter Zugriff: 19.06.2017].

- Khawaji, A., D., Kutubkhanah, I. K., Wie, J.-M., (2008). Advances in seawater desalination technologies. Dessalination 221, 47-69. doi:10.1016/j.desal.2007.01.067.

- Koschikowski, J., Wieghaus, M., Rommel, M. (2003). Solar thermal driven desalination plants based in membrane distillation. Water Science and Technology: Water Supply. 3, 5–6 S. 49–55. IWA Publishing 2003.

- Lattemann, S. (2001). Meerwasserentsalzung. In: Lozán, J- L., Graßl, H., Karbe, L, Hupfer, P., Schönwiese, C.-D., (2001) Warnsignal Klima: Genug Wasser für alle? Climate Service Center. URL: http://www.climate-service-center.de/products_and_publications/publications/detail/062586/index.php.de [letzter Zugriff: 19.06.2017].

- Winter, D., Koschikowski, M. Wieghaus, M. (2011). Desalination using membrane distillation: Experimental studies on full scale spiral wound modules. Journal of Membrane Science 375, 104-112. Doi: 10.1016/j.memsci.2011.03.030.

Weitere Informationen werden vom FIS bereitgestellt.

will be added soon.

Wismut GmbH

Conception and evaluation of a pilot plant membrane processes for the treatment of output water (Abstoßwasser) of the water treatment plant Ronneburg of Wismut GmbH

Funding Period: 01.06.2019 – 31.01.2020

Summary

Mine and leakage water are treated in water treatment plants (WBA) at Wismut locations and then released as output water (Abstoßwasser). At all operated treatment plants radionuclides and heavy metals are separated by precipitation of calcium carbonate and/or precipitation of iron. Hardness, sulphate and chloride stay mostly unaltered. To improve salt retention, combined membrane processes, i.e. ultrafiltration with downstream nanofiltration or reverse osmosis, are tested in a pilot. Aim is to check weather this is applicable for the treatment the above mentioned output water (Abstoßwässer). Tests for colloid eparation are conducted and especially ultrafiltration is examined in regard to a stable plant system operation.

The aim of this project is the determination of operating factors for membrane processes to improve salt retention when treating output water (Abstoßwässer. The scientific support of laboratory experiments for colloid separation as well as the scientific design and evaluation of the pilot project are subject of this economic collaboration.

Further information can be found in FIS.

Possible applications and performance of forward osmosis in industrial water management

Funding period: 01.10.2016 – 30.09.2019

This research project studies the performance and operating behaviour of forward osmosis, which hasn’t been applied for processing in industrial wastewaters in Germany yet. Chosen industry sectors were those, whose process water cannot be reused until now for economic reasons or that have to be treated with energy-intensive procedures. To cover the wide range of applications in manufacturing industries, the following industry sectors are observed:

- Production of food and feed

- Production of paper and cardboard and products made from them

- Production of cars and car parts

- Metal production and metal working

- Production of metal products

With the work performed, a contribution is made to technology description and the further development of forward osmosis for the application in the industry to establish a sustainable and economic procedure for industrial process water treatment. In preliminary investigations water of the above mentioned industry sectors was examined and analysed in regard to parameters that could be relevant for forward osmosis (pH-value, conductivity, salinity, concentration of organic contents, concentration of fouling and scaling creators (scaling: accumulation of crystalized salt on the membrane), type of particle and particle concentration). Afterwards a systematisation of these waters according to the above mentioned parameters will take place to select a representative range of water for tests. These wasters serve as feed solution in the forward osmosis, whereby the draw solution is an economic, concentrated saline solution. In parallel to the pre-examination, designing, assembly and setup of a pilot plant in laboratory scale takes place. The core is a membrane test unit for testing and characterisation of different membranes as well as for performance tests with different waters as feed solution.

The following experimental tests are done in regard to the used waters and membrane materials. Therefore, the waters that have been characterised in the preliminary tests are treated with commercially available forward osmosis-membranes as well as with recent developments. The results serve the evaluation of the performance of the membranes. The following factors are analysed and collected:

- Pressure drop through membrane

- Volume flow of feed and draw solution and their alteration through measurement of mass differences

- Level of concentration of the feed and/or dilution of draw solution as well as the slipping of dissolved compounds through the membrane based on conductivity measurements and analysis of single substances

- Fouling and scaling on the membranes’ surface

- Material composition of the feed and draw solution and the surface layer

- Structural change of the membrane through membrane autopsy

- Overtopping speed at membrane surface

- Possibilities for cleaning the membranes

The evaluation of the test happens ongoing and in coordination with the involved parties from the industry. For an application-oriented summary the results are theoretically described using a developed transport model. It describes the diffusive and convective transport of dissolved compounds through forward osmosis-membrane in regard to the influence and interaction of material and compound parameters. The developed and validated model is then used to work out new plant parameters.

Based on the test and model results possible applications and limitations are put into a guideline, for enterprises to use forward osmosis for the treatment of industrial water. As well, an economic feasibility study takes place to compare it to the currently applied processes.

The final aim is, to answer the following important questions about the application of forward osmosis based on the water compounds of process water:

- Which water yield or which concentration is feasible?

- Which membrane material is suitable?

- Which operating factors have to be set (flow speed, volume flow rates, cleaning and striping intervals)?

- Which pre-treatment is necessary (if applicable)?

- Which investment costs and operating costs are to be expected?

Further information can be found in FIS.

Optimising the pulse technique for the use in drinking water treatment

Funding Number: 3000640376 – 100240188

Funding Period: 01.03.2016 – 31.05.2019

Summary

Aim of this research project is the further development of a novel procedure to oxidise organic water components in drinking water treatment using high-voltage pulse technique.

The pulse technique is based on the formation of cold plasma (ionised gas at room temperature and ambient pressure) by the input of extremely short high-voltage pulses into a water-air intermixture. In this process highly reactive radicals like ozone are formed. Those are brought into the raw water that needs to be treated and attack and degrade unwanted organic water components.

The scientific basis of pulse technique was already worked out in the ZIM joint-project “Innovative high-voltage pulse technique and its application to eliminate anthropogenous trace substances in drinking and waste water” (Funding Number KF2088005MKL0). Further research is needed according to the chemical fate of water components, which are especially relevant to drinking water treatment (e.g. humic substances in treatment of surface water). Furthermore it needs to be examined, if the pulse technique is a reasonable addition or alternative to the conventional procedure according to its applicability and economic efficiency.

By the means of need for research following objectives are defined:

- It is evaluated to what extent the pulse technique can improve drinking water quality.

- A concept for a procedural optimized industrial scale realization of the pulse technique is developed.

- Finally an evaluation of the pulse technique compared to conventional processing technologies considering scientific, plant-specific and economically criteria follows.

To reach the targeted aim following investigations are scheduled:

- Conception and setup of a pilot plant to use in drinking water treatment,

- implementation and evaluation of test series at the pilot plant,

- optimisation of the pilot plant in consideration of its electro technical and hydraulic construction and

- comparative evaluation of the pulse technique.

Further information can be found on FIS.

WTA Vogtland GmbH (08/2017 - 11/18)

FlexMemHybrid

Funding Period:

01.08.2017 - 30.11.2018

Project topic:

Water is increasingly polluted due to anthropogenous pollutant emission by industry and municipality (e.g. micro pollutants). In addition to the reduction of pollutant discharge, recycling of industrial water using new technological and economic solutions that require less space, are easy to handle, have a high efficiency and a high capacity is a possibility for a better use of resources. This R&D project aims to develop a flexible industrial wastewater treatment system on the base of an innovative modular membrane hybrid system. The focus lays on the procedural and plant-specific integration of adsorption, ion-exchanger and reaction modules into a dipped ultrafiltration membrane system. The FlexMemHybrid is characterized by a low space requirement and a fast integration of every treatment stage and an easy regenerability or replacement of modular units. Furthermore the demands of „industry 4.0“ are implemented in the production and the operation of FlexMemHybrid.

Further Information can be found on FIS.

Procedural examination for arsenic removal at IAA Bielatal

Funding period:

01.08.2018 - 15.10.2018

Project topic:

The Lausitzer und Mitteldeutsche Bergbau-Verwaltungsgesellschaft mbH (LMBV) manages the former industrial sedimentation plant Bielatal of the former stannery Altenberg/Eastern Ore Mountains. To divert the leakage water from IAA Bielatal into the river Biela the arsenic content is supposed to be reduced. It is intended to build a plant to reduce the arsenic contamination. The planning and building of a treatment plant at IAA Bielatal requires accompanying procedural tests for an optimized rating of the water and sludge treatment as well as to choose a selection of treatment processes as well as a treatment for mechanical sludge dewatering.

Further information can be found on FIS.

Energy efficiency in heatset web offset printing (EHROD)

Funding number: 03ET1329A

Funding period: 01.10.2015 - 30.06.2018

Zuwendungsgeber/Projektträger

Project overview

Heatset web offset printing is the most widespread printing process worldwide for printing magazines, catalogues and advertising brochures in medium to long runs. From an energy perspective, heatset web offset printing offers significant opportunities for improvement. Due to the increase in energy costs as a proportion of manufacturing costs (3% to 10% in the last 10 years) and for ecological reasons, the printing industry is interested in increasing the efficiency of the energy-intensive drying process of the heatset web offset printing process. The primary approach is to heat the dryers, which until now has been done using combustion gas from natural gas and solvent combustion.

A promising and completely new concept is the conversion of the drying process to indirect heating with process steam from a flexible combined heat and power (CHP) system based on an integrated gas-steam (GiD) process. Heating the dryer with steam from a GiD plant also has the advantage that fluctuations in heat demand do not affect the efficiency of the CHP plant.

The GiD process was investigated at the TU Dresden as part of a project funded by the BMWi (FKZ 0327485A), and a medium-sized printing company now has the opportunity to implement this CHP technology in conjunction with another energy efficiency measure in an industrial environment.

The EHROD project is intended to investigate and optimise this new drying technology in terms of process and plant technology as well as operational management in order to prepare its technical implementation in heatset web offset printing and beyond.

Theoretical and experimental investigations are to be carried out to achieve the objectives of the project. For the experimental investigations, a GiD test facility with process water recovery is available at the TU Dresden and test dryers are available in the aforementioned printing plant, which result from the conversion of conventional dryers without any development having taken place with sufficient consideration of their system integration and corresponding scientific support. Studies are to be carried out on these steam-heated test dryers to determine optimal operating parameters for a high quality of printed products with minimum energy input. Based on the test results, concepts for the next generation of dryers will be developed. According to the heat requirements of the dryers, the operating mode of the GiD system is to be optimised with regard to low fuel input. In addition, the possibilities for water recovery in the GiD process and for improving the heat utilisation of the printing plant are to be investigated. The project will conclude with an evaluation of the achievable ecological and energy-economical effects of the novel drying technology.

Further project information can be found in FIS.

Supervision of a two-stage tendering procedure to improve the efficiency of the waterworks Boxberg – phase 1: creation of a water processing concept and support of the pre-planning stage

Funding period:

01.05.2018 - 31.05.2018

Project content:

The drinking water in the north of the district Görlitz is supplied by the Schwarze Pumpe waterworks. In the future the raw water quality won’t be sufficient to treat it to drinking water due to the increasing sulfate pollution by the surface mining. Currently it is assumed that by 2022 Schwarze Pumpe won’t provide drinking water anymore. As a consequence the drinking water supply of a whole region needs to be restructured. In doing so, the Boxberg waterworks will become important. According to the demographic developement of the region, it has been shut down gradually. Now the Boxberg waterworks will be adapted to the state of the art according to the expected raw water quality, ensuring safe drinking water supply. The research work refers to the inspection and evaluation of the provided data, especially of the raw water quality. The results should provide suitable treatment options to determine one that is technically practical, ecologically and economically sustainable and to prepare a two-stage tender procedure. Finally the preferred option will be evaluated and determined.

Further information can be found on FIS.