Dec 03, 2024

Efficient Planning for 3D-Printing

Additive manufacturing offers immense potential for a wide range of applications, enabling the production of highly complex and customized components without the need for costly mold and tooling processes. A key challenge lies in efficient production planning, particularly in the assignment and sequencing of components on the available 3D printers.

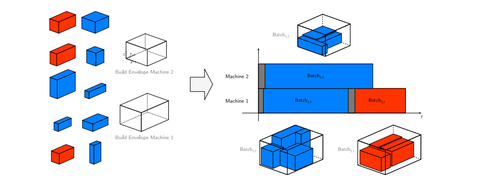

In their new publication, titled “A new branch-and-cut approach for integrated planning in additive manufacturing,” the team of Felix Tamke, Leopold Kuttner, and Benedikt Zipfel addresses this issue by developing an exact solution approach that integrates two subproblems: grouping components into production batches and subsequently assigning these batches to multiple machines.

Based on the ideas of Benders decomposition, the method ensures that the solution considers both optimal packing of components and efficient allocation to the machines. Extensive computational studies demonstrate that the new algorithm delivers significantly better solutions compared to existing approaches, reducing cycle times by an average of 18.7% and by up to 97.6%.

Benedikt Zipfel, Felix Tamke, Leopold Kuttner, European Journal of Operational Research

https://doi.org/10.1016/j.ejor.2024.10.040