OLAFF - Optimizing the layout for manufacturing fibrous-material containers at Diehl BGT Defence

The project arose in the course of the reconstruction of a workshop for manufacturing fibrous-material containers at the Röthenbach a. d. Pegnitz site carried out by the Packaging Systems division of Diehl BGT Defence GmbH & Co. KG. In the course of the project, a proposal was developed as to how to arrange the existing machinery from the old workshop together with new machinery and more generous storage areas so as to optimize the material flow and hence minimize transport routes. A particular challenge here was the diversity of the various products and product variants that were to be manufactured using the new layout without major conversion works.

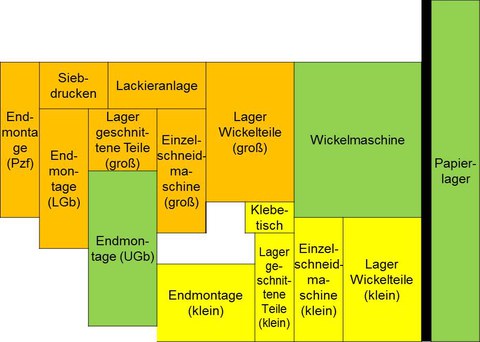

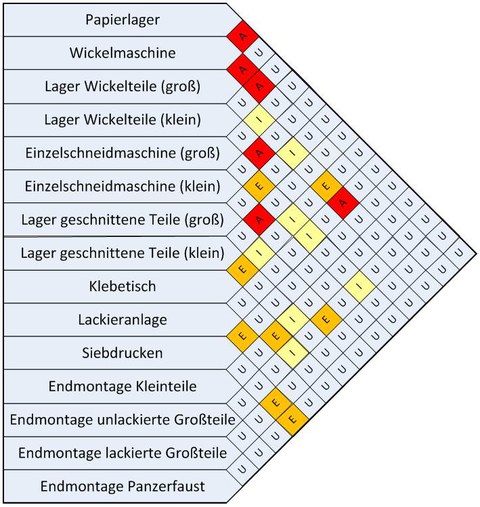

Accordingly, the project team initially carried out an on-site analysis of the manufacturing processes for four selected product groups and represented them in the form of a process graph. Based on this, the team performed an assessment of the manufacturing layout created by the client in respect of resulting transport routes. In parallel with this, the project team developed its own layout proposals, using, among other things, the computerized relationship layout planning (CORELAP) method, with which students on the Diplom courses have already become acquainted in the Strategic Production Management class. The layout proposals created in this way were likewise assessed in respect of transport routes and further developed in close collaboration with the client, it being possible, in the end, to achieve a significant reduction in transport routes and actually implement the proposed layout.

Partner

Diehl BGT Defence GmbH & Co. KG, Bereich Verpackungssysteme

Duration

01/2012 – 02/2012

Involved Persons

Prof. Dr. Udo Buscher

Dipl.-Wi.-Ing. Gerhard Aust

Dipl.-Wi.-Ing. Birgit Keller

Tommy Schulz