Fundamental R&D work on methods for state monitoring of transport and storage containers for spent fuel and heat-generating high-level radioactive waste on prolonged intermediate storage

Sub-Project: Thermographic and radiographic measurement methods

Motivation:

The continuing search for a long-term storage of highly-active nuclear waste in Germany requires a prolonged intermediate storage of spent fuel in dry storage casks at the power plant sites. For the moment it is not sufficiently clear if there may be a loss of integrity of fuel rods during such long times, e.g. due to rising pressure from the gaseous product of nuclear decay. An extrapolative modelling of the radiochemical and thermomechanical material behavior is challenging regarding a final evaluation. Therefore, it is of public interest to find and potentially implement methods which can provide information about the condition of the storage container inventory.

Objectives:

The overall aim of the project was the evaluation of different physical measurement principles and methods for non-invasive monitoring of the condition of the container inventory in case of a prolonged intermediate storage. With that, options were determined to identify changes of the spent fuel and inner container structure over long periods without opening the container. A suitable method or a combination of methods would be a significant contribution regarding the long-term safety of intermediate stored highly-radioactive waste. Such a method would provide evidences about the transport and conditioning ability of the waste before its transfer to the repository.

Methods and results:

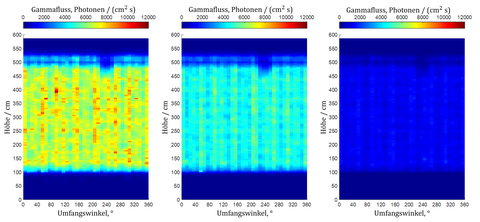

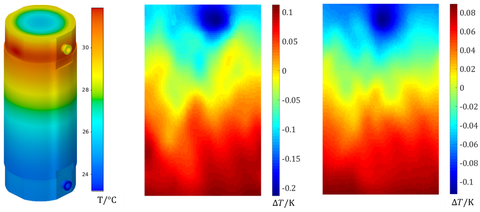

First, it was investigated whether the radiation (gamma radiation, neutrons) and heat emitted by the fuel elements can be used to detect long-term changes in the cask inventory from the outside. In both cases, realistic cask geometries, loadings and storage periods were taken as a basis. For the use of radiation, radiation fields outside a cask were calculated and analyzed with the help of Monte Carlo simulation for given scenarios. It turned out that a fuel displacement of several centimeters would be detectable. For the heat radiation measurement, coupled FEM-CFD simulations were carried out. Only very weak sensitivity was found, so that thermography was excluded as a potential monitoring method. For both approaches, the simulated sensitivities were confirmed in simplified experiments by the project partner. Furthermore, the project investigated whether an imaging analysis of changes in the nuclear fuel inventory is possible by detecting high-energy cosmic muons. Monte Carlo simulations were also used for this. Good sensitivity was found for longer measurement durations. Finally, methods of active and passive acoustic spectroscopy were investigated with regard to their suitability for long-term monitoring. Both the possibility of detecting bursting processes within the cask and vibration analyses were taken into consideration. Both methods are very sensitive to inventory changes. However, it has been shown that the transferability of experimental and simulation data to real geometries and the condition characterization of the inventory are not clearly possible.

Gamma flux distribution outside the side wall in the case of fuel sinking by 9 cm in a fuel assembly close to the wall after 5 years (left), 10 years (center) and 50 years (right) of storage.

Left: Simulated temperature distribution at the outer cask wall after 40 years of interim storage. Middle and right: Difference of the temperature distribution in the case of sinking of fuel by 9 cm in a fuel element close to the wall minus the temperature distribution of the normal state after 40 years of interim storage (middle) and after 100 years (right). The vertical dimension corresponds to the height of the container and the horizontal dimension to the circumferential angle.

Publications:

M. Wagner, R. Rachamin, S. Schmidt, D. Fiß, S. Reinicke, A. Kratzsch, U. Hampel

Simulation-based investigation of suitability of thermography and muon flux measurements for non-invasive monitoring of transport and storage containers for spent fuel

Proceedings of Annual Meeting on Nuclear Technology, 29.-30.05.2018, Berlin, Germany

R. Rachamin, U. Hampel

Feasibility study for detection of fuel assemblies state inside sealed dry storage casks using external gamma flux measurements

Proceedings of 20th Topical Meeting of the Radiation Protection & Shielding Division of ANS, 26.-31.08.2018, Santa Fe, NM, USA

M. Wagner, R. Rachamin, S. Schmidt, D. Fiß, S. Reinicke, A. Kratzsch, U. Hampel

Non-invasive multi-modal monitoring of transport and storage containers for spent fuel

Proceedings of 9th World Congress on Industrial Process Tomography (WCIPT9), 02.-06.09.2018, Bath, UK

U. Hampel, A. Kratzsch, R. Rachamin, M. Wagner, S. Schmidt, D. Fiß, S. Reinicke

Investigations on potential methods for the long-term monitoring of the state of fuel elements in dry storage casks

2nd Workshop on Safety of Extended Dry Storage of Spent Nuclear Fuel, Gesellschaft für Anlagen- und Reaktorsicherheit (GRS), 2018, Garching

U. Hampel, A. Kratzsch, R. Rachamin, M. Wagner, S. Schmidt, D. Fiß, S. Reinicke Investigations on potential methods for the long-term monitoring of the state of fuel elements in dry storage casks

Kerntechnik, 83, 6 (2018): 513-522

U. Hampel, M. Wagner, S. Schmidt, D. Fiß, S. Reinicke, A. Kratzsch

Investigations on potential methods for the long-term monitoring of the state of fuel elements in dry storage casks: recent results

3rd Workshop on Safety of Extended Dry Storage of Spent Nuclear Fuel, Gesellschaft für Anlagen- und Reaktorsicherheit (GRS), 2019, Garching

R. Rachamin, U. Hampel

Feasibility assessment of using external neutron and gamma radiation measurements for monitoring the state of fuel assemblies in dry storage casks

Annals of Nuclear Energy, 135 (2020): 106975

M. Wagner, S. Reinicke, A. Kratzsch, U. Hampel

An analysis for detecting potential relocation of the inventory of dry storage containers during prolonged interim storage via changes in the wall temperature fields

Nuclear Engineering and Design, 366 (2020): 110749