Micro processing

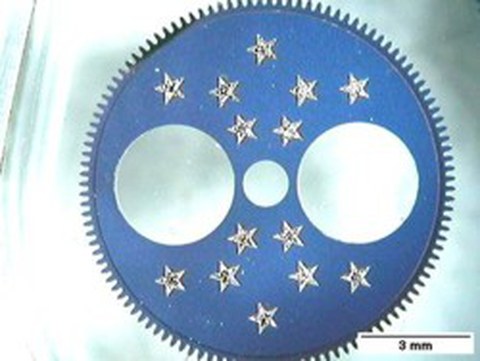

The micro-processing of innovative and highly developed materials with minimized structures increasingly requires tools with high precision. These demands apply for a wide range of industrial applications. They start with the micro-structuring of fluidic elements for polymeric Lab-On-Chio systems, continue with micro-drilling of fuel nozzles and might end with the micro-cutting of stents and sensors for the aerospace or the micro-structuring of ceramics for micro reactors.

This is a very special problem for the micro processing, because not every technology is suitable for a precise and reproducable processing within the micrometer range. To produce high precision structures by laser material processing, special requirements are necessary with respect to system engineering and laser sources.

By using short pulse lasers it is possibly to process nearly all materials with highest precision and reproducability.

Our main research priorities are:

- micro-cutting and joining of different materials

- surface pre-treatment with laser (cleaning)

- micro-structuring of different materials

- surface functionalization for life science applications