PVD coating

Simulation system SimCoat: Optimization of coatings in vacuum systems

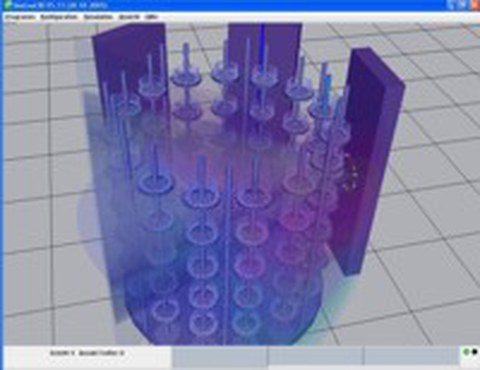

The vacuum arc coating has been established for the industrial deposition of tribological , hard protective films. The coating systems enable a variety of parameters and operating conditions. The process simulation, developed at the LOT, simulates the coating process in a preferably realistic manner. Thus, it is possible to minimize the experimental

expenses and the costs and, additionally, to optimize the coating conditions.

During the coating, particles (e.g. carbon) of the highly ionized coating plasma impinge on the component with high energy. The resulting growth in layers and the film characteristics are basically dependent on the conditions within the coating chamber.

Thus the following, already realized requirements to the simulation system, result:

- image of the geometrical and kinematical conditions of the particular coating system.

- virtual equipment by importing complex components from CAD data

- simulation of the coating process

- consideration of shadowing- and undercut effects

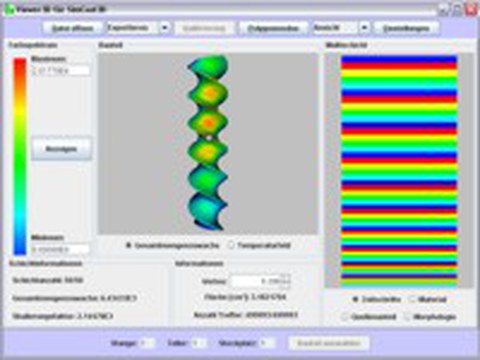

- evaluation by means of different physical calculation models

Evaluating the different results by the help of program-internal post processors the following questions can be answered:

- film thickness distribution on the component’s surface

- multilayer structure at selected points

- plasma source input for the film construction

- temperature field calculation

- morphology of the film structure

Apart from the cost reduction the simulation gives insight with respect to:

- chosen equipment

- film quality

- selection and placement of plasma sources

- process limits ( e.g.temperature)

- operation parameters