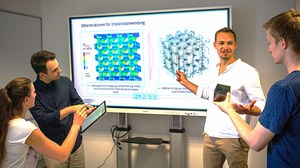

Integrated process, material, and structural analysis

Our research focuses on the development and application of efficient data-based methods for analyzing the complex process-structure-property relationships in modern materials and structural components. AI-based approaches integrate experimental data with results of high-performance simulations.

© TUD/NEFM

© TUD/NEFM

Competences in Research

The Chair's core research areas are as follows:

Data-driven process, material and structural analysis

- Microstructure characterization and reconstruction

- Description of process-structure-property (PSE) relationships

- Exploration of PSE relationships and inverse materials design

- Virtual sensing and classification for load and stress determination

- Digital twins for condition-based maintenance

Development of data- and model-based simulation methods

- Physics-augmented neural networks for material modeling

- Data-driven multi-scale simulations with automatic sampling

- Phase-field modeling of crack propagation and structural evolution processes

- Modeling of coupled field problems

Experimental characterization and modeling of material behavior

- Damage and failure behavior of additively manufactured materials

- Process-induced influence on material service life

- Inelastic, strain rate-dependent material behavior of polymers

- Damage behavior of fiber-reinforced composites

- Magnetosensitive elastomers and fluids

- Experimental validation of material models

Details of our activities can be found in the research projects section.