Jan 19, 2024

Distributor Effects on Liquid Hold-Up in Rotating Packed Beds

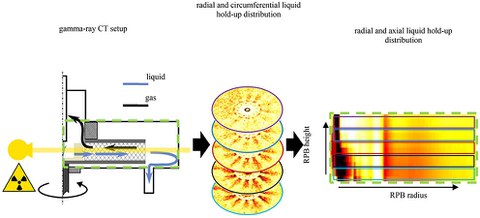

Although it is known that a loss in separation performance is caused by liquid maldistribution, there is only marginal knowledge of liquid distribution in rotating packed beds (RPBs). As a result, the exact influence of the liquid distribution on separation performance in RPBs is not fully understood. Therefore, this study focuses on the influence of different liquid distributors on the liquid hold-up distribution of rotating metal foam packing inside RPBs. Liquid hold-ups were measured noninvasively using γ-ray computed tomography (CT), and water/air was the system under investigation, operated at atmospheric pressure, temperature of 20 °C, liquid flow rate of 60 l h–1, F-factor of 2.3 Pa0.5, and rotational speeds up to 900 rpm. For the first time, the liquid hold-up distribution in the axial direction of a rotating metal foam of an RPB could be accessed, which allowed the identification and quantification of occurring liquid accumulation at the rotor plates. Furthermore, the liquid hold-up distribution through the entire opaque packing could be visualized for different operating conditions by synchronizing the CT with the rotational speed of the rotor. The use of a single-point full-jet nozzle was more prone to cause liquid accumulation at the rotor plates than that with a rotating baffle distributor with 36 baffles. For comparison, circumferential liquid maldistribution was also observed by using a rotating baffle distributor with 12 baffles.

Distributor Effects on Liquid Hold-Up in Rotating Packed Beds