Equipment

The chair has various equipment for experimental and theoretical analysis of reactive and non-reactive multiphase processes. Our facilities allow for comprehensive research on hydrodynamics, mass transfer, reaction kinetics at high temperature and pressures of up to 150 bar. Additionally, we have commercial software tools for process simulation, flow simulation and plant design.

Test Facilities

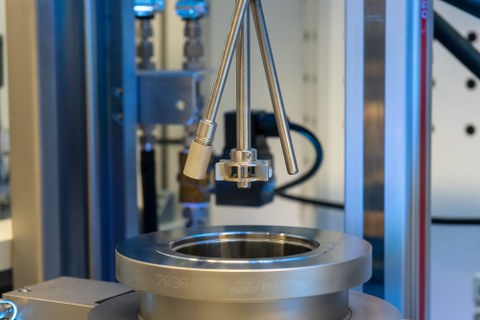

- Autoclaves

- Fixed-bed differential loop reactor

- High-pressure tubular reactor

- Three-phase hydrodynamic facilities

- Supercritical solvolysis system (under construction)

Lab equipment and analytics

- Gas chromatography / mass spectrometry (GC-MS)

- High performance liquid chromatography (HPLC)

- Refractrometer

- Laboratory precision scales

Catalyst Preparation

- Drying oven and muffle furnace

- Tube furnace with protective gas

- Catalyst and particle analysis: particle classifier, comminution techniques, screening machines, laser diffraction spectrometer, electron microscope

Software

- Process simulation: aspenONE Engineering Suite, MatLab

- Flow simulation: Fluent, OpenFoam

- Plant design: Aveva PDMS

- 3D-CAD: AutoCAD, Autodesk Inventor, Solidworks