Comparison of operating conditions and flue gas cleaning technologies for the reduction of fine dust emissions - using the example of crematories

Title

Comparison of operating conditions and flue gas cleaning technologies for the reduction of fine dust emissions - using the example of crematories

Research associate

Dipl.-Ing. Martin Köhler

Duration

01.11.2018 – 31.10.2019

Funding

H. Wilhelm Schaumann Stiftung

Partner

VMT Verfahrens- und Messtechnik Saalfeld GmbH, Grimm Aerosol Technik Ainring GmbH & Co. KG

Motivation

At present, an intensive debate on the subject of particulate matter is taking place and a committed research is done to reduce particulate emissions. Initially, traffic plays a major role as a major source. In addition, all other emitters in urban areas as well as in agriculture and forestry must be considered.

Exemplary for a fine dust source with completely different flue gas cleaning systems, as they also occur at other plants in the field of energy conversion as well as in agriculture, a systematic consideration of operating conditions and plant engineering with regard to fine dust emissions is to be carried out in the present research project. For this exemplary consideration crematories are suitable, since they show few differences in the main process engineering, but have very different variants of exhaust gas cleaning. Thus, a direct assignment of operating conditions and plant engineering to the quality of the emission reduction is possible.

The research results can be transferred to other processes in the future, since flue gas cleaning systems, as they are usually found behind crematoria, can also be used in processes for the energetic utilization of agricultural residues, for the disposal of animal carcasses and in the food processing industry.

In the completed research project, a reliable database was created for the first time through measurements at ten crematoria with differently designed exhaust gas cleaning lines.

Technology of cremation

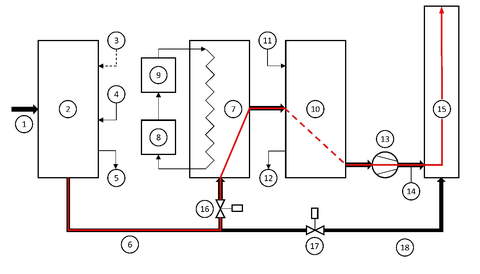

Figure 1: Scheme of cremation process according to VDI3891

(1 – coffin entrance device, 2 – crematory oven, 3 – burner, 4 – combustion air supply, 5 – urn ash discharge, 6 – flue gas duct, 7 – flue gas cooler, 8 – heat utilization (optional), 9 – heat exchanger, 10 – multilevel flue gas cleaning, 11 – feed of sorbent (optional), 12 – dust discharge, 13 – fan, 14 – emissions monitoring, 15 – stack, 16 – shut-off valve, 17 – bypass gate valve, 18 – bypass duct)

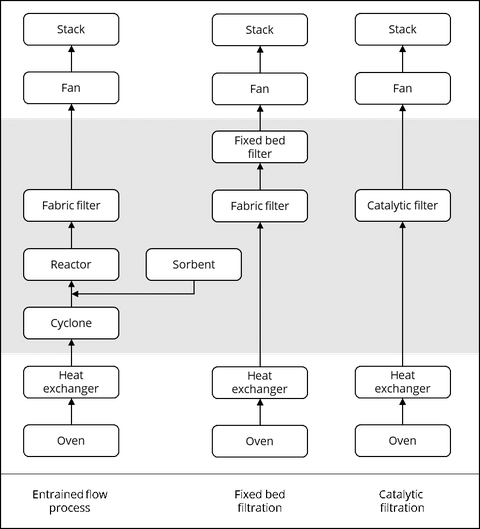

Figure 2: Flow diagrams of flue gas cleaning process (changed from VDI3891)

Results

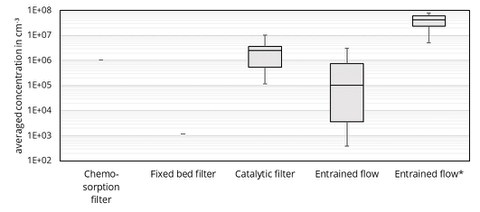

An SMPS+C measuring system (measuring range 5 nm - 450 nm) in combination with the hot gas sampling probe was used for the measuring campaigns. An overview of the number of ultrafine particles in relation to the flue gas cleaning technology is shown in the following figure 3.

Figure 3: Concentration of ultrafine particles in relation to the flue gas cleaning technology

The widest range is shown by plants with entrained flow processes. With appropriate maintenance, however, these systems also achieve the lowest total number of ultrafine particles in the stack. In contrast, entrained-flow processes with poor maintenance (marked with an asterisk*) are less capable of retaining them and achieve emissions that are three orders of magnitude higher than plants with maintained filter systems. For plants with chemosorption filter and fixed-bed adsorber, only one measurement was available for evaluation in each case, so no clear statement can be made.

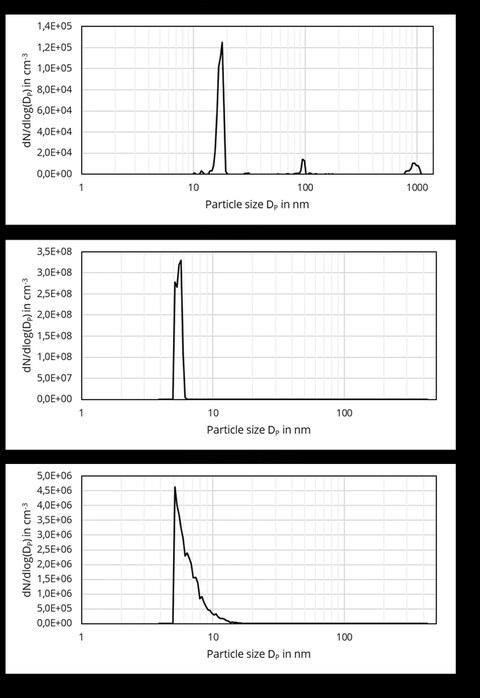

Not only the total number of ultra-fine particles in the exhaust gas is decisive for the evaluation of emissions, but also the particle size distribution, exemplary shown in figure 4. High emissions are always accompanied by a very small particle size, often at the lower resolution limit of the measuring system of 5 nm.

Figure 4: Examples for the particle size distribution of ultrafine particles in the flue gas of different crematories

The complete results of the measurement campaign were summarized in a final report, which can be requested from the H. Wilhelm Schaumann Foundation (). The results were also published in:

- Köhler, M.; Ohle, A.; Beckmann, M.; Graf, S.; Tettich, F.; Steinau, S.: Ultrafeine Partikel im Abgas von Humankremationsanlagen. Poster zum 3. Symposium „Ultrafeine Partikel in der Außenluft und in Innenräumen“. 19.9./20.9.2019, Berlin

- Köhler, M.; Ohle, A.; Beckmann, M.; Graf, S.; Tettich, F.; Steinau, S.: Ultrafeine Partikel im Abgas von Humankremationsanlagen. In: Gefahrstoffe – Reinhaltung der Luft, 2020, Ausgabe 01-02, S. 19-24