REA Test Facility

Test facility

- Test plant for flue gas desulfurization by means of scrubbing processes

- Connection to the dust firing test plant, thus direct comparison possibility for the desulfurization behavior in air and oxyfuel mode.

- Operation as spray, pouring or packing absorber

- Two absorber towers for dual-flow or operation as dual-circuit scrubber

- Several sampling points and showcases

- Oxidation step (for gypsum production) can be carried out internally or as well as in an external container

- Suspension feed can be heated, cooled and stirred

- Air operated diaphragm pumps for suspension

- Outlet side induced draft fan

Plant control

The air-operated diaphragm pumps, agitator, fan and lighting can be switched on or off via the control cabinet. The flow rates of the air-operated diaphragm pumps are controlled via manually operated flow control valves.

Examination possibilities, measurement data acquisition and evaluations in the laboratory

To record the measurement data, the measurement signals such as PH value, temperature and pressure are connected to the LabView program. The measurement data are recorded and stored as a function of time.

The following parameters influencing absorption during wet scrubbing can be investigated with the test facility:

- Liquid/gas ratio

- pH value sump

- pH value absorbent

- Absorptive concentration

- Gas velocity

- Solids mass fraction in the absorber vessel

- Solids mass fraction in the absorbent

- Use of additives

The test plant has temperature measuring points at the inlet and outlet nozzles, in the absorber vessel, in the external oxidation and in the heating or cooling circuit.

Furthermore, the gas volume flow at the outlet as well as the relative gas humidity and the gas compositions before and after each absorber tower can be determined.

For the analysis of the absorbate, pH and redox probes are available in the absorber vessels and the external oxidation. Samples of absorbate and absorbent, flue gas condensate, and flue gas can be analyzed in the laboratory for composition and purity.

Technical parameters

| Raw gas flow rate: | 30 Nm³/h |

| Operating temperature: | up to 80 °C |

| Dimensions: | Inner diameter absorber towers: 125 mm Absorber tower heights: 2 m/3,5 m |

| Container volume: | 2x 140 l (Sump tank) 400 l (external oxidation tank) |

| Material: | PP-H |

| Suspension circulation: | 800 l/h per absorber tower |

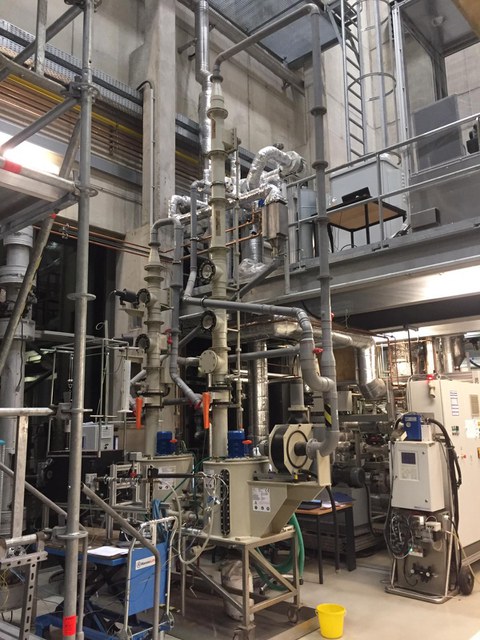

Abb. 1: Test facility

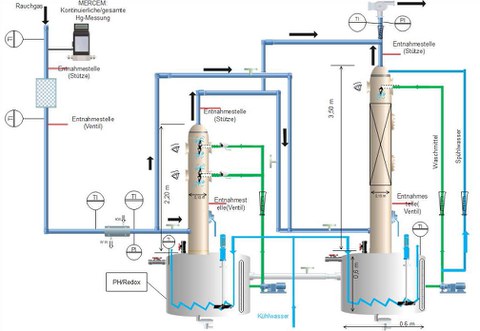

Abb. 2: Scheme