Counter-rotating furnace

Reverse rotation oven

| Processor: | Dipl.-Ing. Sebastian Grahl |

| Term: | 10/2008 till 07/2009 |

| Cooperation partners: | Nuclar power plant A+V project development and plant construction Ltd. Bautzen |

Brief description

- Listing a simplified calculation model for the thermotechnical layout of a reverse rotary kiln for target production

- Numeric simulation by means of the calculation model, with the help of a specially designed calculation algorithm in “MathCAD” for stationary operation and instationary heating by the thrust processes necessary, using “MathCAD 14” software for numeric simulation

- Variation of parameters to investigate the main cause variables on heat transfer and plausibility check by means of a practical example

- Calculation of heat transfer through the kiln ceiling and kiln walls, as well as of the heat loss through the kiln’s surface depending on ambient temperature, in order to construct the kiln walls properly

- Determining the temperatures at the diffusion barrier for secure condensation in the separate kiln sections, in order to properly construct the kiln walls

- Determining the temperatures at the ceiling beams of the kiln for strength calculations

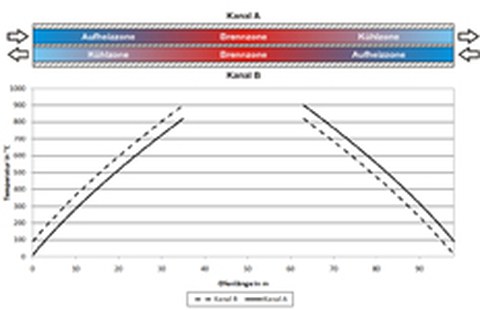

Longitudinal section through the reverse rotary kiln

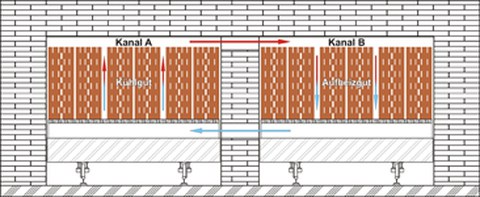

Cross section through the reverse rotary kiln