DRESDEN-TANK

Examination for the evaluation of safety aspects regarding the release of graphite dust from the primary coolant circuit of gas-cooled nuclear reactors

To answer the question on the severity of radionuclide release during a depressurization event in a high-temperature reactor (HTR) knowledge of the transport behaviour including deposition and remobilization of graphite dust is of key importance. Furthermore, it provides a basis on determining the radiological risk for inspection and maintenance work during normal operation.

Therefore, the test facility DRESDEN-TANK (Dust RESuspension and DEpositioN in TANK geometry) was set up. It provides an experimental access to investigate the fundamental understanding of dust behaviour and possible ways for retention under HTR conditions. On the one hand, this facility allows to conduct investigations on isolated temperature-driven effects, such as the behaviour of individual particles on the wall surface. On the other hand, it provides the possibility to examine superimposed effects like multi-layer particle depositions. However, the main objective is the evaluation of thermochemical reactions concerning the long-term behaviour and are carried out with individual particles and dust layers on sample surfaces respectively, steel for instance. In addition, these experimental data are mandatory for simulation calculations in the community.

Current setup of the pilot plant

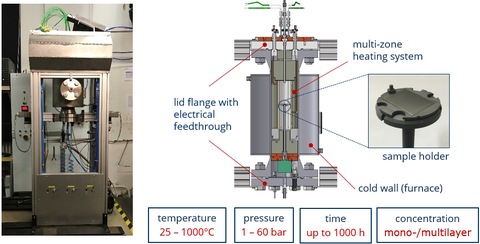

DRESDEN-TANK has been designed to thermally treat samples for up to 1000 h at temperatures up to 1000 °C and pressures of about 60 bar in a helium atmosphere. A schematic overview of the structure and the sample environment is shown in Figure 1. DRESDEN-TANK is a high-temperature autoclave. Its pressure-resistant sample chamber is used to thermally anneal graphite-dust-laden metal samples in various atmospheres (helium, argon, nitrogen or air).

This test facility has been constructed as a cold wall furnace. The temperature in the sample chamber can be regulated between 0 - 1000 °C. Dense insulation protects the outer wall during operation. The temperature is controlled by an axial multi-zone heating (3x1 kW). Through cover flanges on the top and the bottom are equipped with electrical feedthroughs for the heater.

Table 1 lists the most important parameters, the possible fluids (fields of application) and the measurement technology:

| High temperature autoclave with rotating cooled sample holder | |||

| Inner diameter | Ø = 55 mm | ||

| Volumen | V = 0,57 Liter | ||

| Vacuum capability | Medium vacuum pmin < 1 mbar | ||

| Maximum temperature | Tmax = 1050 ºC | ||

| Maximum pressure | pmax = 60 bar | ||

| Size of the test samples | A = 22,5 x 30 mm² | ||

| Working media | |||

| Argon | Helium | Nitogen | Air |

| Measuring technology | |||

| Temperature measurement | Thermocouples type K | ||

| Gas sensor | Oxide sensor, gas chromatography | ||

| Pressure monitoring | Pressure sensors, pressure relief valves | ||

| Process monitoring | Coolant flow and video surveillance | ||

| Supervisor | |

| Sponsoring institution | GRS |

| Projects | STAUB-II STAUB-III |