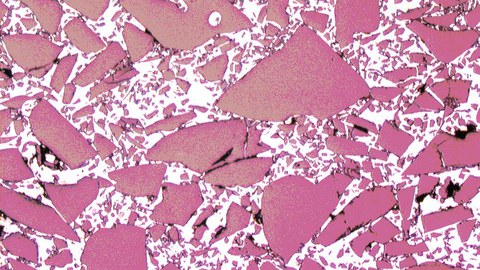

© Fraunhofer IFAM Dresden

© Fraunhofer IFAM Dresden

Chair of Powder Metallurgy

Powder metallurgy is a fascinating manufacturing technology for producing high-precision metallic components in large quantities. It is essential for the production of special materials, e.g. hard metals, porous components or refractory metals. The various manufacturing processes, including the state-of-the-art processes from the field of powder-based additive manufacturing, allow immense flexibility in material composition and microstructure formation and, thus, offer the possibility of setting unique microstructures and properties. With these possibilities, answers can be given to current industrial questions in connection with the energy and mobility turnaround. The research concentrates on the development of high-performance materials and powder metallurgical as well as additive generative manufacturing technologies and the understanding of microstructure - process - property relationships. The focus is on mobility, energy technology and medical technology. Examples of materials are functional materials (soft magnets, thermoelectrics, cellular materials and structures), composite materials for thermal management as well as materials and processes for hydrogen production and storage.

The Chair of Powder Metallurgy works thematically closely with the Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM, Branch Lab Dresden. Prof. Dr.-Ing. Thomas Weißgärber is holder of the Chair of Powder Metallurgy since 1 April 2022; at the same time, he is Institute Director of Fraunhofer IFAM.