Causal Condition Monitoring of Axial Piston Pumps through Wear Detection in Correlation with Operating and Load Conditions

Task / Objective

The aim of the research project is to develop methods for cost-efficient condition monitoring of axial piston pumps and to create the basis for estimating the remaining service life. The minimum requirements for data acquisition are to be determined in order to identify both wear and the load collectives that lead to it. The following research questions are to be answered:

- Quantification: Is it possible to detect different levels of wear depth and thereby quantify wear? Can the degree of wear be identified continuously for remaining useful life estimation?

- Cost-effectiveness: What sensors at what sampling rate are the best, to not only predict the wear condition but also identify the operating point—i.e., speed, pressure, and swash plate angle?

- Causality: Is simultaneous identification of the operating condition and pump wear feasible with a sensor configuration tailored to the desired level of detail?

- Scalability: Can the developed features and machine learning methods be transferred to other pumps of different sizes or from different manufacturers?

Methodology

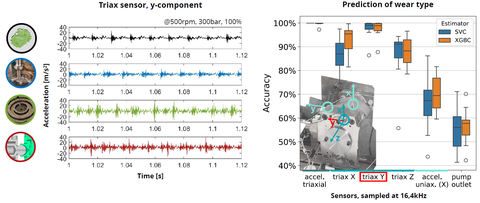

Three realistic types of wear were introduced into a 92cc axial piston pump: valve plate cavitation in three severity levels, axial clearance between slipper and piston, and wear on the slipper sealing surfaces. These defects represent early damage stages and primarily result in a slight increase in internal leakage. Comprehensive sensor measurements were conducted across nearly 100 different operating conditions, varying speed, pressure, and swash plate angle.

To assess transferability, cavitation damage on the valve plate was also introduced into a 160cc pump from a different manufacturer and thoroughly measured. In addition to time- and frequency-domain analysis, machine learning models were developed using Support Vector Machines and XGBoost algorithms, trained and tested with various datasets. The key findings are summarized below.

Results

The procedure developed for implementing an economical sensor concept demonstrates that a single triaxial acceleration sensor can be used to obtain many information about the pump condition. In addition to the current operating point (pressure, speed and swivel angle), it is also capable of predicting the type and extent of damage, including leakage, with the assistance of trained machine learning (ML) models. This information is necessary for the estimation of the remaining service life, a pivotal milestone in the transition from a preventive maintenance strategy to a predictive maintenance strategy.

The accuracy was found to increase significantly to almost 99% by reducing the number of labels from several defect types to only two labels ("good" and "damaged"). This was achieved despite a reduced sampling rate of 4.1 kHz and the use of only the y-axis. This constitutes a constituent element of the triaxial sensor. This approach is consistent with practical requirements, where the primary concern is often to ascertain the functionality of a pump. In order to ascertain the precise nature of the fault, it is necessary to determine whether the item is "healthy" or "faulty".

In order to facilitate the detection of wear in real applications, it is advantageous to minimise the scatter caused by different operating conditions, since these have been shown to have a significant impact on the vibration spectra, thereby complicating the process of detecting the condition of the pump. This objective could be realised, for instance, by employing a predefined test cycle under controlled conditions, such as when initiating the machine. Furthermore, it is conceivable that different models could be trained for different operating ranges, with the capacity to measure or predict variables that remain variable, such as temperature or swing angle.

A comparison of the raw data revealed clear differences in the vibration behaviour of the various pumps of different sizes and manufacturers. A regression model trained with pump 1 was unable to identify any correlations to leakage in the data from pump 2. Subsequent training of the model with reference data from the second pump ("boosting") did not result in any enhancement in the validation with unknown wear data. Further research is required in order to ascertain the transferability of the aforementioned pumps to other models.

The project (funding code 01IF22012N) was funded by the Federal Ministry of Economics and Climate Protection (BMWK) with funds from the Industrial Collective Research (IGF).

Duration: 01.02.2022 bis 31.01.2025

The final report of the project can be obtained from the Forschungskuratiom Maschinenbau e. V. (http://www.fkm-net.de) (postal address: Lyoner Str. 18, 60528 Frankfurt am Main, e-mail: info@fkm-net.de).