Mechanical watches

|

Full title: |

Mechanical watches (MBS) |

| Duration: |

07/2009 – 12/2011 |

|

Contributors: |

Dipl.-Ing. Benjamin Röseler (TU Dresden, IMM) |

| Financing: | Sächsische Aufbaubank - Förderbank |

| Objective: | Based on the specific requirements towards the toothing in mechanical watches, an optimal toothing for the application as gear train toothing shall be determined as well as its calculation. The scientifically proven knowledge about toothing properties, loading, efficiency, kinematic behaviour, accuracy sensitivity (Genauigkeitsempfindlichkeit) and the calculation of relevant toothing parameters constitute the basis for the optimal toothing in this project. |

| Approach: |

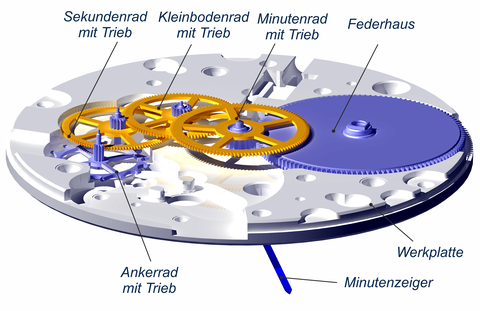

The drive energy stored within the mainspring barrel is transmitted via intermediary wheels to the fast spinning escape wheel. Close attention should be paid to a low-loss and steady energy transmission to minimize time deviation. Among particular requirements which are defined by the small dimensions, the influence of contaminations and the unhindered movement of gears are:

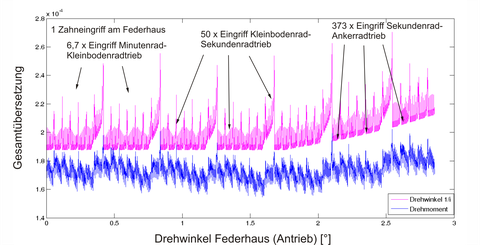

The complete representation of the gear train within a multibody system simulation enables a comprehensive analysis and evaluation of parameters. |

| Results: |

For example with a modified involute toothing, the influence of each stage is visible in the overall gear ratio of the gear train (energy transmission from the mainspring barrel to the escape wheel). The torque transmitted from the escape wheel to the escapement exhibits a fluctuation of up to 25 % under constant driving torque from the mainspring. The fluctuation results from the transmission characteristics of the four gear stages. This underlines the influence of the gear train toothing on the time deviation of the watch. The stages of mainspring barrel - minute wheel and minute wheel – third wheel have the largest influence on the torque ratio in the overall gear train because they transmit the largest tooth forces. |