Adaptive individualisierte Implantate zur großflächigen kranioplastischen Versorgung

| Laufzeit | 01.01.2025 – 30.06.2027 |

| Gesamtprojekt | Adaptive individualisierte Implantate zur großflächigen kranioplastischen Versorgung |

| Teilprojekt | Algorithmen für 3D-Datenverarbeitung |

| Akronym | AdInKranio |

| Finanzierung | EFRE FuE-Verbundprojektförderung 2021-2027 (SAB) |

| Förderkennzeichen | 100741563 |

| Projektleitung | |

| Bearbeiter | Dr.-Ing. Philipp Sembdner |

| Partner |

INNOTERE GmbH, Radebeul |

Das Forschungsprojekt AdInKranio zielt auf die Entwicklung innovativer, individualisierter Implantate zur Behandlung großflächiger Schädeldefekte ab. Die herkömmlichen Methoden zur Rekonstruktion dieser Defekte stoßen regelmäßig an ihre Grenzen, indem sie nicht die individuellen Bedürfnisse der Patienten hinsichtlich Form, Größe und biologischer Verträglichkeit erfüllen können.

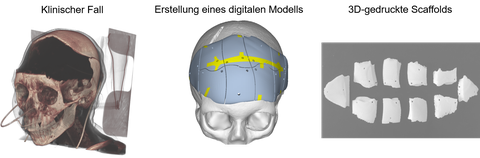

In diesem Projekt sollen neue, adaptive Implantate entwickelt werden, die individuell an die spezifischen Anforderungen jedes einzelnen Patienten angepasst werden können. Im Mittelpunkt steht die Etablierung einer durchgängigen und effizienten Prozesskette, die es ermöglicht, solche Implantate schnell und präzise zu fertigen. Dabei kommt eine besonders innovative Technologievariante der additiven Fertigung (3D-Druck) zum Einsatz, die gleichzeitig eine hohe Flexibilität und Präzision in der Produktion bietet.

Ein unikales Merkmal der zu entwickelnden Implantate ist ihr mehrteiliger Aufbau, der es ermöglicht, sie flexibel an unterschiedliche Bedingungen anzupassen. Diese Modularität ist entscheidend, insbesondere bei der Behandlung von Kindern, deren Schädelform und -größe im Laufe des Wachstums noch Veränderungen unterliegt. Die Implantate sollen sich den verändernden Bedingungen anpassen können, ohne dass zusätzliche chirurgische Eingriffe notwendig werden. Darüber hinaus sollen die Implantate verschiedene Materialeigenschaften vereinen, eine dichte Schicht zum Schutz des Gehirns und eine poröse Schicht, die das Knochenwachstum fördert und so die Integration des Implantats in den Schädelknochen verbessert.

Um die bestmögliche Lösung zu finden, werden im Projekt Methoden zur Aufteilung der Implantate in verschiedene Segmente erforscht. Diese Segmentierung erleichtert die Herstellung und die chirurgische Handhabung der Implantate. Dabei werden Ansätze untersucht, um die Teile sicher miteinander zu verbinden, wobei Materialien eingesetzt werden, die sich im Laufe der Zeit biologisch abbauen können.

Ein weiterer Schwerpunkt des Projekts liegt auf der Entwicklung eines Simulationsmodells, mit dem die mechanische Belastung und die Haltbarkeit der Implantate bereits vor ihrer Herstellung virtuell getestet werden können. Diese Simulationen sollen helfen, die Implantate so auszulegen, dass sie den Anforderungen des Alltags standhalten und gleichzeitig den Heilungsprozess unterstützen.

Die Projektpartner arbeiten eng mit Fachärzten zusammen, um sicherzustellen, dass die Implantate sowohl technisch als auch hinsichtlich des klinischen Einsatzes ausgereift sind. Die Validierung des Gesamtsystems erfolgt durch die Herstellung von Demonstratoren, die in realen Szenarien getestet werden. Darüber hinaus sind wirtschaftliche und insbesondere regulatorische Aspekte zu berücksichtigen.

Mit dem Vorhaben wird eine entscheidende Verbesserung der Versorgung von Patienten mit Schädeldefekten erwartet, indem individualisierte, flexible und höchst biokompatible Implantate entwickelt werden, die den aktuellen Stand der Technik in der Medizintechnik erheblich erweitern. Die Ergebnisse dieses Projekts sollen in Zukunft einen wichtigen Beitrag zur Verbesserung der Lebensqualität betroffener Patienten leisten und die chirurgische Praxis nachhaltig voranbringen.