Development of a concept for the data workflow and necessary software solutions for individual planning, modelling and production preparation of an augment (sub-project)

| Runtime | 01.07.2018 – 30.06.2020 |

| Overall Project | Development of an integrated process for individually planned and additively manufactured implants for bone augmentation |

| Funding |

BMWi funded within the framework of the AiF-program ZIM |

| Project staff |

Dipl.-Ing. Peter Koch |

| Dr.-Ing. Philipp Sembdner | |

| Partners |

Organical CAD/CAM GmbH |

|

Zahntechnik Schönberg |

|

|

Universitätsklinikum Dresden, Klinik und Poliklinik für Mund-, Kiefer- und Gesichtschirurgie |

|

|

INNOTERE GmbH |

Motivation

A suitable local bone bed is necessary for the use of dental implants. If this is not available due to many years of toothlessness, trauma or tumour, a build-up (bone augmentation) of the atrophied areas is necessary. The provision of patient-specific bone replacement structures (augments) offers potential for the planning of dental implants and associated prosthetics that would not be feasible with the current state of the art. A form-fitting augmentation that reflects the defect geometry is desirable for aesthetic, medical and economic reasons. It can thus enable the restoration of the bone shape, facilitate implantation and positively influence the ingrowth behaviour of the bone. In addition, the ingrowth behaviour can be promoted by introducing a targeted individual porosity. This is only possible by manufacturing using 3D printing processes. Furthermore, economic advantages are foreseeable due to material savings and improved surgical conditions. Patient-specific manufactured augmentations can only be provided if the patient-specific CT and DVT data are fed into a computer-assisted modelling and manufacturing process.

Objective

The aim of the project is to develop and implement a continuous digital process chain for planning, modelling and additive manufacturing of individual bone replacement structures in the field of maxillofacial surgery. The combination with the process for navigation-supported dental implantation as well as the interface between practitioner and designer are to be taken into account in the development. The constructive goal is the development of a new augmentation design depending on medical specifications, which has other properties in addition to form fit. This includes the development of new types of surgical instruments (e.g. positioning templates). The project is intended to produce an individual augmentation with associated surgical instruments, software for their planning and a service (process chain) as a prototype.

Project content

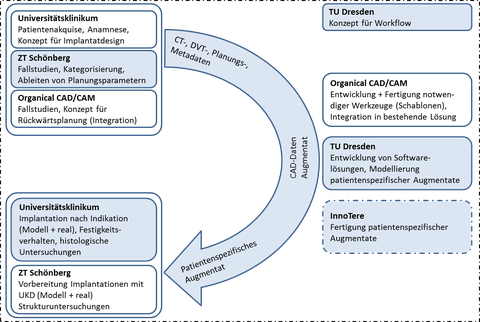

The interaction of the individual project partners and the project contents are shown in the following figure:

© BMWi

© ZIM