Determination of roughness inside components using CT data and correlation with classical methods (sub-project)

| Runtime | 01.08.2017 – 31.01.2020 |

| Overall project | Qualitätsmanagement für die sichere und robuste additive Produktion (QUALIPRO) |

| Funding | BMBF |

| Project staff | |

| Partners | APWorks GmbH (Airbus Group) |

|

Trumpf GmbH & Co. KG |

|

| AM Metals GmbH | |

|

Fraunhofer IFF, IPK, IWS, IWU |

|

| SIEMENS AG | |

|

Symate GmbH |

|

| CONTACT Software GmbH | |

| Professur für Werkzeugmaschinenentwicklung und adaptive Steuerungen |

Motivation

Competitive companies need a process landscape and quality management to use and integrate additive technologies into series production. The QualiPro - Quality Management for Safe and Robust Additive Production project aims to develop clear quality routines along the additive process chain. This is intended to create the basis for the certification of additive technologies and to establish the framework for cooperation in the value creation network.

Objective

- Development of a quality management system for additive manufacturing in the powder bed to ensure robust additive processes

- Continuous data acquisition along the additive process chain and evaluation of the data to assess the resulting component quality as well as the measures to adjust the process parameters

Approach

In order for companies to be able to use additive manufacturing in the series production process, factors that are decisive for competition such as cost, time, quality, productivity, process capability and flexibility are taken into account. The focus in QualiPro is on powder bed-based laser beam melting. Data is recorded throughout the additive process chain and linked to the component quality achieved. Measures for optimising additive production are derived from the findings.

The QualiPro technology project consists of 4 interlinked modules:

First, the framework conditions are analysed. These form the basis of the project and focus on the future possibilities for quality assurance in the value creation processes. Quality management is then designed along the additive process chain. The data recorded inside and outside the process will be analysed in the data management module. Finally, the automated creation of a component certificate on the basis of demonstrator components should be successful.

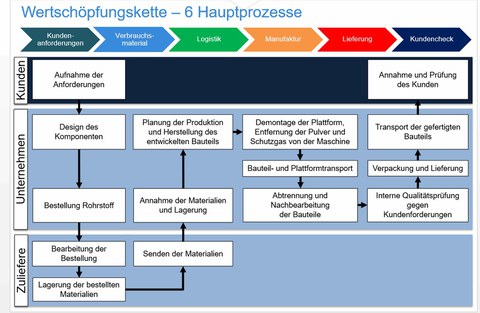

Additive value chain

The consideration of value chains and processes for additive production in different industries is the starting point of QualiPro. The business cycle is considered, which takes into account the design, construction, production and testing levels with the respective processes, resources and work steps. An essential component is the structured listing of manufacturing processes that are relevant to value creation.