TitraBot

The analysis of chemical parameters plays a crucial role in quality assurance, as well as in research and development, especially in industries such as pharmaceuticals, environmental analysis, the food industry and chemical production. The relevant chemical parameters, which are often determined using titration methods, include the OH number, the chemical oxygen demand (COD) and the content of active substances in pharmaceutical products.

Despite the continuous development of laboratory technology, most chemical analysis processes still rely heavily on manual intervention. This applies to sample preparation as well as the performance of the tests and the subsequent evaluation of the results. One example of a method that is still largely manual is titration, a process for determining concentrations in solutions. Although automated titrators exist that facilitate certain steps of the process, important work steps such as sample preparation, reagent selection, device calibration and data post-processing are still often dependent on laboratory staff. These manual interventions not only make the processes time-consuming, but also error-prone and reduce the efficiency and reproducibility of the results.

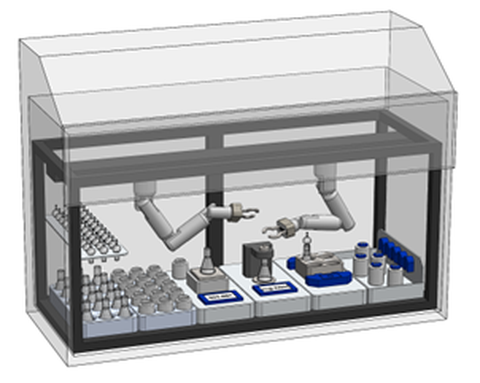

As a system for the complete automation of chemical identification, from sample preparation to analysis, clearly does not exist, the company SmartLab Solutions GmbH and the Chair of Bioprocess Engineering are to undertake such a development in this project. The scope of the project includes analyses that are carried out using titration methods. However, the possibility of integrating a different method should always be retained due to the modular platform character. The fully automated process control is intended to provide the user with as much walk-away time as possible during the processing of the entire batch volume, during which no user interaction is required. The overall system has a modular design as shown in Fig. 1 and consists structurally of a platform into which different process modules are integrated. The step-by-step processing of the process chain in chemical key figure determination is performed by the functionality of the individual modules integrated in the system. The higher-level platform transports samples and vessels to the respective modules. The system is controlled by the user via a process interface where the desired workflow can be selected, parameterized and started. The process data is stored in structured form in a database and made available to the laboratory's LIMS system via a corresponding interface.

Schematic representation of the automation platform for the determination of chemical key figures envisaged in the project

Project funding:

ZIM AIF

Project manager:

© Mann

© Mann

Project researcher

NameDipl.-Ing. Christoph Otto

SmartLab-systems, lab automation

Send encrypted email via the SecureMail portal (for TUD external users only).

Project partner:

Project duration:

01.07.2025-31.08.2027