Sep 01, 2024

BIOMOPAC

Molded fiber tray made from 100% bagasse (sugarcane residue)

Bio-based functional molded fiber packaging from regionally sourced agricultural residues

| Duration | 09/2024 - 08/2027 |

| Funding | BMFTR | DLR-PT (IGSTC 2+2) |

| Funding Code | FKZ123456 |

| Contact | |

| Keywords | Bio-based packaging, molded fiber, agricultural residues, barrier, recycling, life cycle assessment |

Aim

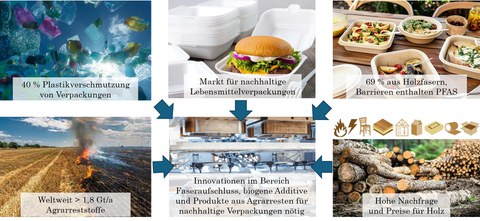

BIOMOPAC aims to develop bio-based and fully recyclable packaging made from agricultural residues - as a sustainable, fossil-free alternative to conventional packaging solutions.

- An international network of research institutions and companies from Germany and India is working together along the entire value chain - from the raw material to finished packaging products.

- The molded fiber packaging (MFP) is composed entirely of plant-based materials that are locally sourced and processed into molded structures with natural barrier properties using newly developed mechanical processes.

- One focus is on the application of microfibrillated cellulose (MFC) as a barrier layer that eliminates the need for fossil-based additives while maintaining recyclability.

- TU Dresden is responsible for the development of fiber preparation and process design for the application-adapted use of the residual materials - as a substrate or as a barrier.

- At the end of the project, a scalable process concept will be available to manufacture market-ready, functional packaging solutions with a demonstrably lower environmental footprint (based on life cycle assessment) than conventional products.

BIOMOPAC combines technology, the circular economy and international collaboration to advance the transition toward sustainable packaging solutions.

partner

Links to

Funding reference