Steam turbine control valve

To analyse the operational stability of a steam turbine control valve at part load conditions, a scaled and simplified control valve test rig has been constructed. Derived from smaller steam turbines, the test rig allows the operation from full load to low part load conditions and allows major insights into flow regimes across the whole operating window.

Structure

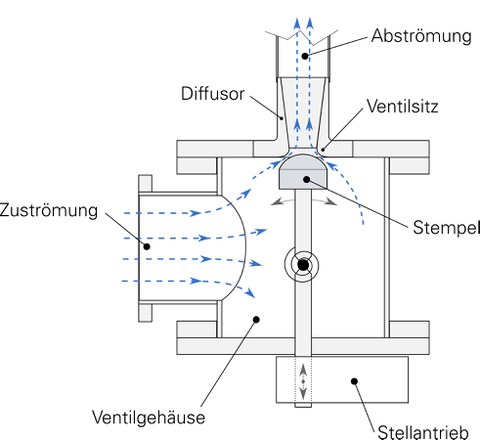

The scaled control valve is integrated into the high pressure test facility at the Centre for Energy Technology at Technische Universität Dresden and is supplied with compressed air. Entering the test rig, the incoming air is first decelerated and redirected before it passes the throttle area that is formed by the valve head and valve seat. After a diffuser, the air is then released into ambiance through an exit pipe.

The opening of the valve can be adjusted by an actuator positioned underneath the valve chest, defining the operating point along with the inlet pressure of the valve.

To analyse the vibration behaviour of the valve, the valve stem that supports the valve head and connects it to the actuator features an elastic component, that can be either set to an quasi-stiff or an elastic configuration. By adjusting the stiffness, different dynamic characteristics can be assessed.

Research focus

Across the different test campaigns, the behaviour of the valve is categorized. At first, steady measurements were used to retrieve the flow characteristics of the valve. Using time resolving measurements of wall pressures on the valve head and diffuser wall, the unsteady pressure field has been obtained and was used for validation of numerical setups.

By measuring the vibration, displacement and forces, the dynamic behaviour of the valve of both the quasi-stiff and elastic configuration has been assessed. Along with the pressure field the measurements allow to evaluate the interaction between the flow field and the dynamics of the valve.

Technical data

| Operating area | |

| Medium | Air |

| Pressure ratio | 0.2 – 1.0 |

| Mass flow rate | up to 0.5 kg/s |