Equipment

Table of contents

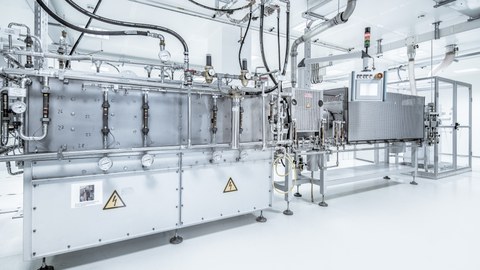

Solvent wet spinning plant

- Development of multifunctional and high-strength polyacrylonitrile precursor fibres

- Use of tailor-made renewable raw materials

- Innovative synthesis and modification of biopolymers and fossil educts

Bicomponent melt spinning plant

- Research and development of innovative high-performance and functional fibres

- Application-oriented research and processing of fibres on an industrial scale

- Technology development for the production of tailor-made melt spun fibres

- Modelling and Simulation of Biko Melt Spinning Processes

- Development and construction of the plant technology for the Biko melt spinning plant

Stabilisation line

- oxidative pretreatment in four heating zones between 200°C and 300°C

- Temperature control accuracy with +-1K per heater and +-5K over the heating zone

- separately adjustable dwell time and stretching per heating zone enables the generation of an individualised property profile

Carbonisation line

- Low temperature (up to 1050°C) and high temperature (up to 1500°C) furnaces for industrial and research process investigations

- Four individually adjustable temperature zones per oven with +-5 K/min

- Inert gas atmosphere with <1ppm oxygen content

Sizing module

- Individually applied coatings for thermoplastics & thermoset matrices

- Stress-varying sizing application for application-specific compacting of fibre bundles

- Drying at temperatures up to 275°C

Contact angle measuring system DSA 100

- Measurement of static contact angles

- Computer-aided image interpretation in accordance to various mathematical approaches

- Compact dimensions due to vertical camera positioning

- Measurement of contact angles of 2-dimensional substrates

- Determination of surface energies in accordance to accepted methods (DIN 55660)

- Measurement of contact angles of woven and non-woven textiles, coatings, ...

- Characterisation of surface properties (hydrophilicity, capillarity)

Single fibre tensiometer - K100SF

- High-resolution weighing system up to 0.1 μN

- Liquid bath with optional temperature control for up to 100 ml sample volume

- Flexible sample holder

- Measurement of contact angles of fibres and sample plates (tensiometry)

- Surface energy determination of liquids (wilhelmy-plate method)

- Determination of sorption rates

- Measurement of contact angles of fibres down to 5 μm diameter (e. g. carbon, glass, aramid, UHMWPE, ...)

- Characterisation of established or altered surface properties (hydrophilicity, capillarity)

NICOLET 6700 FT-IR - Infrared spectroscopy

- Fourier-transformation spectrometre

- Spectral measurement range 650 cm-1 - 4000 cm-1

- Spectral resolution up to 0.25 cm-1

- ATR-unit (attenuated total reflection) for measuring solid samples

- Varying pressing geometries for plane, powdery or very hard materials

- Characterisation of coatings and formulations

- Identification of fibres and associated materials or contaminations

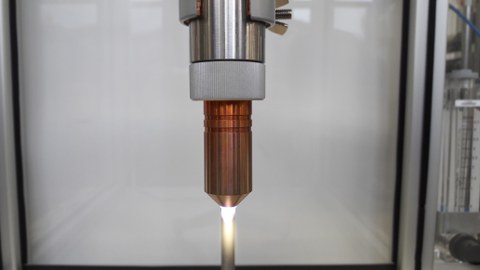

Plasma torch - Relyon plasma generator PG-31

- 700 W - 1000 W

- Various nozzle geometries

- 40 kHz - 65 kHz

- Operating with air and carbon dioxide

- Feeding with precursor

- Single yarn transport device

- PC- controlling and logging via CANBus

- Functionalisation of carbon fibres and other technical high-performance fibres

- Development of material independent joining of textiles

DCN

Moreover, state-of-the-art nanoanalytical equipment is available at one of TUD´s central facilities called Dresden Center for Nanoanalysis (DCN), including transmission electron microscopes, X-ray microscropes, and acoustic atomic force microscopes.

Our Partner