Light and Surfaces

Table of contents

a) Precursor development

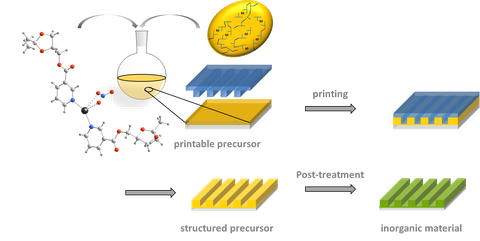

Printing inorganic materials requires the development of molecular precursors with engineered viscosity, wetting behavior and a thermal conversion mechanism into the targeted metal or oxide material without the formation of carbon side products (Fig. 1). The team has developed customized precursors for platinum, silver, gold and oxide coatings (TiO2, SnO2:Sb, etc.) with high transparency and conductivity.

Fig. 1: Customized synthesis of complex molecular precursors for surface coatings

Technologies and applications

- Printing

- Sol-Gel Processing

- Dip-coating

- Spin-coating

- Transparent conductive surfaces

- Semiconductor coatings

- Catalytic coatings

Links

http://pubs.rsc.org/en/content/articlelanding/2015/tc/c4tc02418d#!divAbstract

b) New optoelectronic materials

We develop new absorber materials for solar cells and OLED interfaces as well as new transparent conductive oxide materials.

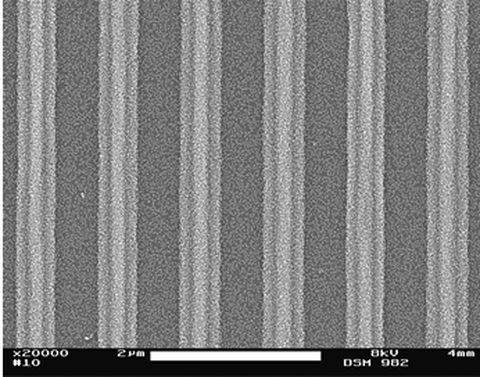

Fig. 2: New optoelectronic materials: Structured GZO film as electrode for OLEDs

Technologies and applications

- Solar cells

- OLED interfaces

Links

http://pubs.rsc.org/en/content/articlelanding/2011/jm/c1jm10886g#!divAbstract

http://pubs.rsc.org/en/content/articlelanding/2016/cc/c5cc10455f#!divAbstract

c) Nanostructured surfaces

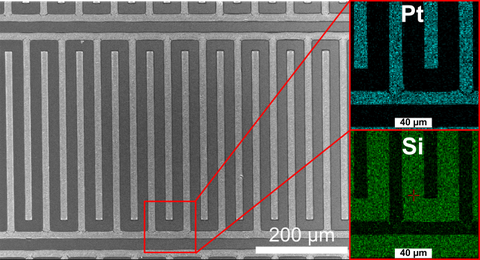

We use nanoimprint technology and µ-contact printing in combination with sol-gel and precursor chemistry for the generation of nanostructured surfaces. We achieve high transparency and high electronic conductivity for optoelectronic applications. Light management is an important target for OLEDs. The periodicity of the surface can tune the efficiency and color of the flat display. Interdigital printed electrodes are ideal components for electrochemical sensors.

Fig. 3: Structured platinum surfaces by nanoimprint lithography for electrochemical sensor applications

Technologies and applications

- Transparent conductive grids

- Sensor electrodes

- Light management

Links

http://pubs.rsc.org/en/content/articlelanding/2013/TC/C3TC00826F#!divAbstract