24.04.2018

New understanding on graphite: a high power cathode material

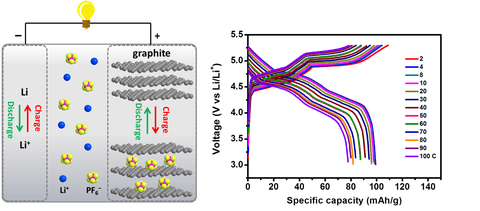

As conventional Li-ion batteries are approaching the bottleneck of energy and power limit, new energy storage technologies with fast-charging feature but based on low-cost materials are highly desirable for future sustainable and scalable applications. To construct next-generation quick-charge batteries, the key lies at developing high power cathodes. However, conventional strategies heavily relied on nanoengineering approaches sacrificing the scalability and battery cost.

The group from cfaed/ Technische Universität Dresden provides another option to build high power cathodes, where inexpensive graphite powders were exploited as the active cathode material. The disintegration problem of graphite cathode, that suffers from large volume change (>130%) during anion (de)intercalation, was well suppressed by utilizing a strong aqueous binder, alginate sodium. Then the mechanically stable electrode functioned as a reliable platform to investigate the electrochemical performance of graphite cathode and reaction kinetics of anion intercalation process. Ultrahigh power density of 42.9 kW/kg at the energy density of 334 Wh/kg and long cycling life (>10000 cycles) were achieved on commercial bulk graphite, surpassing conventional cathodes for Li-ion batteries. The kinetics analysis further revealed that, for the first time, anion intercalation into graphite is a self-activating and fast (pseudo)capacitive process. The kinetical differences between anion intercalation and cation intercalation into graphitic carbon materials were also identified in the paper.

Reference:

Title: Self-activating, capacitive anion intercalation enables high-power graphite cathodes. Adv. Mater., 2018, 1800533.

DOI:10.1002/adma.201800533