Feb 08, 2022

New research project: Double-curved molded parts made from post-processed wood materials

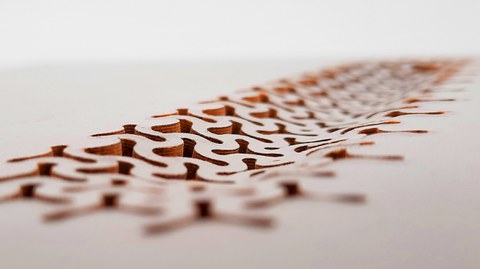

Sample of a molded part from fiberboard with partial perforations to realize double-curved forming

In a current research project, scientists at the TU Dresden in cooperation with the partners Holz-Design Gigler GmbH und Co.KG and MSM Maschinenbau GmbH are investigating the production of double-curved molded parts for furniture and interior design. The focus lies on custom-made products and small series. Existing solutions for the production of such parts are mostly based on non-renewable raw materials such as thermoplastics. Replacing them with flexibly moldable wood-based materials can reduce the consumption of fossil raw materials and thus have a positive impact on the eco-balance. Against this background, scientists from the Chair of Wood and Fiber Material Technology and the research group Geometric Modeling and Visualization (both TU Dresden) have set themselves the goal of making classic wood-based materials formable by creating free spaces for local deformation. These free spaces shall be realized with special perforations that are adapted to the local degree of deformation within the component. The development of the process chain for manufacturing the molded parts is also part of the investigations and the main development goal of the industry partners. The »Holz.Paer.FormT« project is funded from 2021-2024 by the German Federal Ministry of Food and Agriculture (BMEL) via the Agency for Renewable Resources (FNR).

Contact:

Prof. Dr.-Ing. Daniel Lordick

https://tu-dresden.de/mn/math/geometrie/lordick

Deutsche Gesellschaft für Geometrie und Grafik (DGfGG)

http://www.dgfgg.de