Textile reinforced concrete as a basis for a jointless surface of concrete roadways

Table of contents

Project data

|

Titel | Title |

Report in the annual report 2020

TEXTILE REINFORCED CONCRETE AS A BASIS FOR A JOINTLESS SURFACE OF CONCRETE ROADWAYS

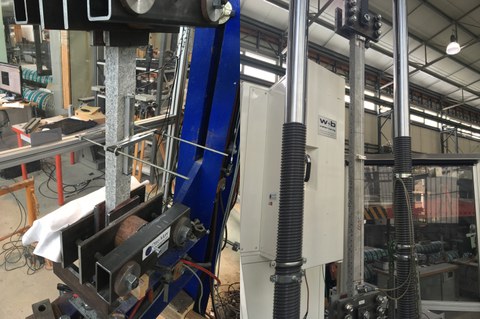

Static test set-up with a tension-strain test element

The project, which was started on behalf of the Federal Highway Research Institute (BASt), investigates the bridging of longitudinal and transverse joints in concrete road pavements. In this research project, a method is being developed to apply a 50–70 mm thick, joint-free repair layer reinforced with carbon concrete to an old concrete layer. The main reason for the use of textile reinforcement is the crack width limitation and the distribution of

individual cracks and joints in old concrete to many smaller cracks in the layer of concrete on top.

The research project is carried out in cooperation with the Ruhr-University Bochum. The knowledge gained in project C3-V4.12 “Carbon concrete for the jointless repair of damaged concrete road surfaces” formed the basis for the current research project. To be able to make a statement about the material combinations, the Institute of Concrete Structures examined expansion bodies with different parameters up to failure.

The focus of the tests was to ensure technical feasibility in practice and to develop the finest possible crack pattern. To determine crack widths and crack distribution, test specimens with two different lengths were produced. The static tests carried out served, in particular, to be able to make a statement about the crack distribution and crack widths. Furthermore, the crack development at temperatures between -20 °C and 60 °C was investigated. In the measuring range of the static expansion elements, 5–6 cracks occurred. By measuring the elongation an average crack width between 0.56 and 0.72 mm

could be determined. A significant influence of temperature on the crack distribution could not be determined during the tests. The breaking load was highest at temperatures of -20 °C. The dynamic tests should allow statements about the fatigue behaviour and the crack pattern. In contrast to the static strain bodies, the dynamic test specimens are only examined at 20 °C and 60 °C.

The dynamic tests carried out so far also showed an evenly distributed, fine crack pattern. A more precise evaluation of the dynamic expansion bodies is still pending after the tests have been fully carried out and completed.

Report in the annual report 2019

TEXTILE REINFORCED CONCRETE AS A BASIS FOR A JOINTLESS SURFACE OF CONCRETE ROADWAYS

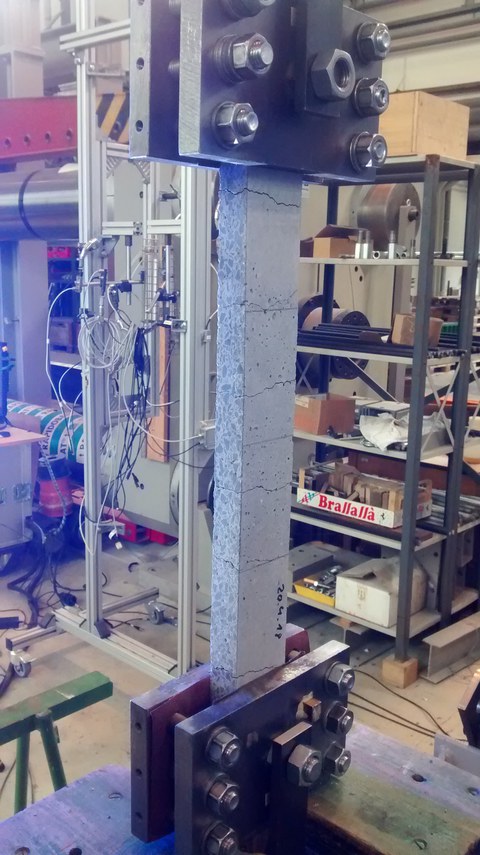

Crack pattern in a specimen of carbon concrete under tension

The common construction of concrete pavements subdivided by longitudinal and transverse joints has a high maintenance due to the required joint seals. In order to be able to avoid this expense in the future. On this basis, on behalt of the German Federal Highway Research Institute (BASt), a method should be developed in this research project which makes it possible to apply a 50-70 mm thick, seamless, textile-reinforced concrete layer to a sub-concrete layer. The textile reinforcement primarily serves the crack width limitation and distribution of the cracks occurring.

The research project, which is carried out in cooperation with the Ruhr-Universität Bochum, is based on initial findings from the C³ project “V4. 12 Carbon Concrete for Seamless Repair of Damaged Concrete Road Pavements”. The investigated materials are expanded to achieve an even finer crack pattern. The tests carried out to initially assess the load-bearing behaviour of the new material combination will be extended to include static and cyclic tensile and flexural tests in the later course of the project. The focus of the textile selection is on ensuring technical feasibility in practice and thus on the possibility of using the developed system for repairing grouted roadway slabs.

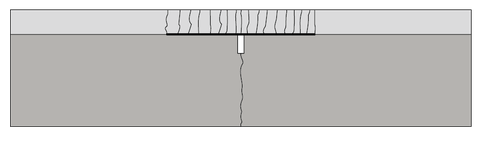

Crack distribution of a crack in old concrete to several smaller cracks in the repair layer

The main requirement for the textile reinforcement structure, in addition to ensuring that the crack pattern is as fine as possible, is the possibility of winding the textile onto a roll in order to achieve a high degree of mechanical production when repairing the roadway. In order to achieve the greatest possible number of cracks within the carbon-reinforced concrete in the area of the joints, a possible bond separation between bottom concrete and top concrete in the area of the joint is also investigated in the course of this project. This composite separation ensures that the movement of the joint is not transferred locally into the upper concrete layer, but is distributed over a greater length over a number of several small cracks in the repair layer.

At the Institute of Concrete Structures, the material combination is investigated under static and cyclic loading as well as under the influence of temperatures between -20 and +60° C.