Sample

Table of contents

Project data

|

Titel | Title |

Report from the Annual Report 2017

To verify the load-bearing capacity of a masonry retention wall in a basement that is exposed to horizontal earth pressure is often difficult. This is the situation, e.g., in the exterior walls of basements, or under patio doors, staircases, etc., where the loads are applied only in one side of the structure. In such a case, it is not possible to vertically transfer the applied bending moments that result from earth pressure. In such cases, the basement wall must transfer the earth pressure in the horizontal direction.

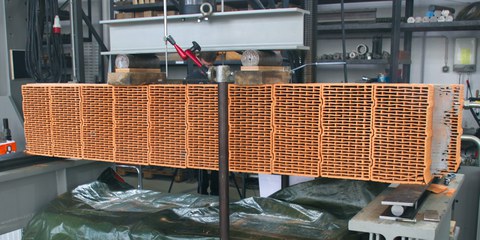

4-Punkt-Biegeversuch an textilbewehrtem Mauerwerk

However, since the bending capacity of unreinforced masonry parallel to the bed joint is very low, there is the possibility to strengthen the bearing joints with continuous layers of textiles made of alkali-resistant glass, carbon or basalt fibres. Textile reinforcement has the advantage of being resistant to corrosion. Also, textiles can also be used in thin bed joints.

The Department of Structural Design of the Faculty of Architecture at TU Dresden has carried out extensive numerical and experimental studies on this topic. The goal is to develop an optimal configuration of material and textile form for use as a bearing joint reinforcement. The focus is on the tensile strength, bond, and durability of the composite material “textile mortar”. At the beginning of the project, there were 4-point bending tests on small beams to examine the bending resistance of textile reinforced masonry. In addition, pull-out and adhesion shear tests were carried out. All experiments were carried out on different combinations of stone, mortar, and textile. We used sand-lime bricks, aerated concrete and perforated bricks as well as various thin-bed mortars and textiles made of alkali-resistant glass and carbon. Depending on the material combination, the bending capacity was larger than ten to twenty times that of unreinforced masonry. The horizontal joints were not weakened. Furthermore, the full shear capacity was reached.

Haftscherfestigkeitsversuch mit textilbewehrter Lagerfuge

Currently, tests are being carried out on a real-scale basement masonry wall. For this purpose, a 2.5 m × 6 m textile reinforced masonry wall with low vertical ballast is subjected to earth pressure. The test results are still open.