Project ABSOLUT - Automated Busshuttle - Selforganizing between Leipzig and the BMW-Terminal

KEY DATA

| Duration: |

01st January 2019 – 31st December 2021 |

| Program: | Bundesministerium für Wirtschaft und Energie IKT für Elektromobilität III, Strategisches Einzelprojekt |

| Budget: | 18,3 Mio. € |

| Grant: | 10,0 Mio. € (6,2 Mio. € TU-Dresden) |

| Project Homepage: | Link Project Website |

MOTIVATION

In Germany and Europe there are a number of demonstration projects with slow (<20 km / h) moving, automated shuttles in local public transport (ÖPNV) [https://www.vdv.de/innovationslandkarte.aspx]. However, only a few of these projects address the technological advancement towards speeds suitable for public transport (> 40 km / h) in order to enable travel times that are competitive with the prevailing private transport.

This is where the ABSOLUT project comes in: The aim is to investigate and show which technologies are required in terms of vehicle and infrastructure in order to fully integrate these minibuses, which have been retrofitted for automated driving in suburban areas, into local transport and to transport passengers safely and as required.

ABSTRACT PROJECT OBJECTIVES

-

Technology development of automated bus shuttles with local speed (40 - 70 km / h) to display driverless (level 4 public transport) public transport operations in public traffic areas

-

Expansion of the driving area and situation control compared to current projects on "virtual rails", which have the goal of pure collision avoidance

-

Representation of line operation with demand stop and on-demand transport by networking customers, control center, vehicles and traffic infrastructure in order to optimize connection security and traffic quality (demand-oriented public transport prioritization).

PROJECT DESCRIPTION

© Ansgar Dietermann

© Ansgar Dietermann

Project Manager

NameDr.-Ing. Steffen Kutter

Send encrypted email via the SecureMail portal (for TUD external users only).

Consortium management: Leipziger Verkehrsbetriebe (LVB) GmbH

Internal Project Partner: Professur für Fahrzeugmechatronik, Institut für Leichtbau und Kunststofftechnik, Professur für Kraftfahrzeugtechnik, Professur für Computergraphik und Visualisierung

External Project Partner: Stadt Leipzig, Leipziger Verkehrsbetriebe (LVB) GmbH, INAVET GmbH, BitCtrl Systems GmbH, Apinauten GmbH, FSD Fahrzeugsystemsdaten GmbH, glts cotech GmbH, IAV GmbH, Sedenius Engineering GmbH, Virtence GmbH

The core idea of ABSOLUT is the development of vehicles and their exemplary use for the test track S-Bahnhof Messe to BMW plant with local speeds and high automation, which will be integrated in the future of the transport services of the Leipzig transport companies.

In addition to the testing and approval of the vehicles, the subject of development is also the pilot operation in public space for testing various deployment concepts. This includes an on-demand 24/7 offer, a booking and information interface developed with the users and the establishment and networking with a control center. Accompanying the study is the user acceptance of autonomous bus traffic.

In the project, business, science and the city of Leipzig work closely together with the transport companies that have taken over the project management. For the predominantly Saxon partners, including small and medium-sized companies, it is possible in the field of digital and communication technologies as well as artificial intelligence to apply and expand the existing competences in order to strengthen the economic and scientific location of Saxony for the future.

The project is a key component of future mobility and is funded by the Federal Ministry for Economic Affairs and Energy. It also reflects the objective of the Free State of Saxony to develop and promote concrete pilot projects for the development and development of autonomous transport systems.

- Optimal sensor concept and design methodology, sensor data fusion, computer vision and model-based object classification for comprehensive and robust object recognition

- Design of vehicle electrical systems and E / E architecture for X-by-Wire vehicles and fully automated driving

- Model predictive online longitudinal and lateral control of the vehicle through optimal control processes for safety and comfort-optimized driving, taking into account release times at traffic lights, traffic situations and charge status

- Consistent design and validation chain for highly automated driving functions and concepts for standardized approval

FOCUS WP 4 "VEHICLE AUTOMATION"

The Professorship for Vehicle Mechatronics heads work package 4 in the ABSOLUT project with the research focus on "Automating Vehicles", which is carried out with the participation of the university partners

- Institute for Lightweight Construction and Polymer Technology - ILK (Faculty of Mechanical Engineering)

- Professorship for Computer Graphics and Visualization - CGV (Faculty of Computer Science)

- Professorship for Information Technology for Transportation Systems - ITVS (Faculty of Transportation Sciences)

and the industrial partners

Further information on upgrading the traffic infrastructure and on the digital test field in Leipzig (WP 5) can be found on the pages of our partner Professorship for Traffic Control Systems and Process Automation.

The EZ10 from the French manufacturer EasyMile is a typical representative of the automated shuttle vehicles currently being produced in small series for public transport. Due to the limited sensor equipment, calculation performance and driving dynamics in the series state, it will be advanced in the ABSOLUT project regarding

- Drive technology from 2 x 8 kW to 50 kW rated power at 48 V

- Underfloor battery 45 kWh instead of 31 kWh behind the bulkhead

- Chassis and steering (only steered front axle)

- ECE-compliant X-by-Wire system

- E/E architecture

- Sensor technology and data processing

- Innovative driver's workplace

As a pure X-by-Wire vehicle, the vehicle enables driverless operation - currently the safety driver controls via joystick and miniwheel in the case of manual driving.

The automation of the electric VW e-Crafter is carried out with a significantly lower implementation risk, even for high driving speeds, since a vehicle that is already approved for this speed range has a conventional driver's workstation for the safety driver (steering wheel, accelerator and brake pedal) with an X-by add-on -Wire system which has been upgraded.

Special challenges are:

- Preservation of the series functionality of the E / E system despite automation intervention

- Flush sensor integration into the vehicle contour in pedestrian-critical areas

- Supply of high-performance computer technology despite limited on-board power supply

In the course of the project, the two completely different vehicle concepts presented below are to be upgraded for automated operation in local public transport at speeds of up to 70 km / h in order to demonstrate transferability and modularity. The sensor concept, sensor data processing and automation framework should remain largely identical and only the vehicle interface and the parameterization should be modified.

Comparison of the vehicles in ABSOLUT

|

Vehicle |

VW e-Crafter | EM EZ10 Complete Renovation |

|

Drive Power |

100 kW | 50 kW |

| Top Speed | 90 km/h | 70 km/h |

| Nominal Voltage | 400 V | 48 V |

| Energy Content of the Battery | 35,8 kWh | 45 kWh |

| Charging Power AC | 7,2 kW | 4,8 kW |

| Charging Power DC | 50 kW | t.b.d. |

PROJECT EVENTS

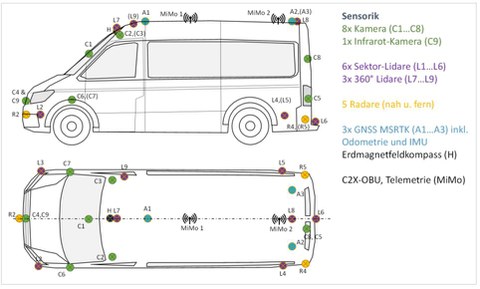

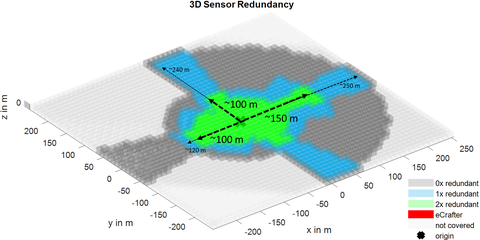

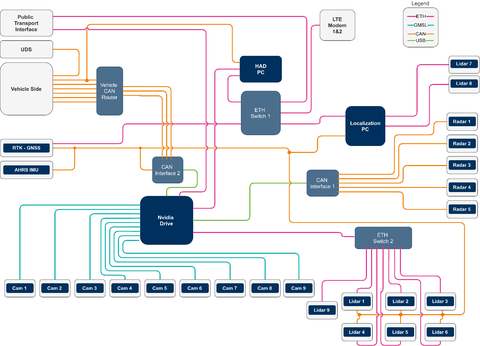

The automation of the project vehicles requires the reliable recording and evaluation of the vehicle environment. The electric VW e-Crafter is equipped with various sensors that enable 360 ° coverage of the environment with three independent sensor systems.

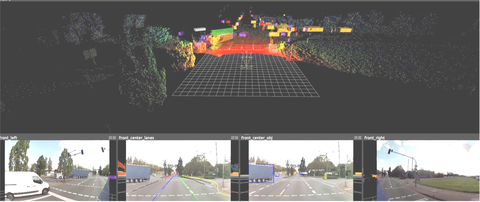

In addition to the series sensors (front radar, front camera and rear view camera), 5 radar sensors, 8 cameras and 9 lidar sensors were integrated into the vehicle as part of the research project (see picture). The combination of radar, camera and lidar technology guarantees precise and robust perception of the vehicle environment even in unfavorable weather conditions (see picture).

For a highly precise determination of its own position, the vehicle is equipped with 3 GNSS antennas on the roof and a geomagnetic field sensor [see also chapter on localization]. Two MiMo antennas, also placed on the vehicle roof, enable communication with the infrastructure (e.g. traffic lights, GNSS correction data services) and the transmission of telemetry data to the control center and developers.

The high bandwidth of the incoming sensor data represents a challenge for the data processing system in addition to the robustness required for permanent use and the need for continuous monitoring of one's own perception horizon.

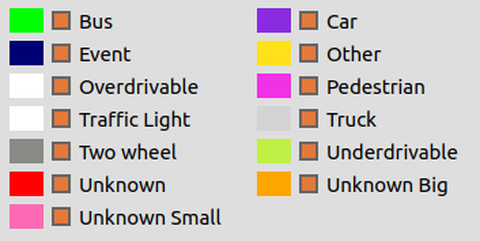

Schematic functional representation of the system for sensor data processing

For this reason, an Nvidia Drive AGX platform is used to process the sensor data for recording the surroundings, whose strengths lie in particular in the extraction of information from camera images. This system is supplemented by a separate CarPC for localization and self-state estimation. This merges the signals of the GNSS system with those of the IMU and the 360 ° lidare [see also chapter on localization].

By implementing it as a distributed system using the Robot Operating System (ROS), all information is available on both systems.

An environment model aggregates everything from the computer vision system, the eigenstate estimation and the C2X interface to form a consistent image of the vehicle environment. On the basis of this information, a third computer system (HAD-PC in the picture) can make a driving decision or plan a path to be followed.

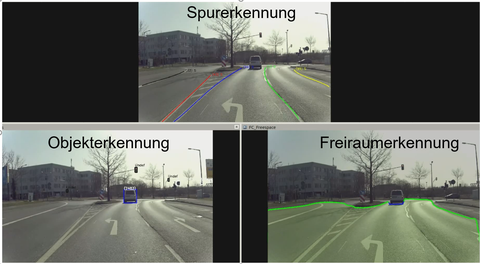

In order to be able to use the data from the camera system, pre-trained ML models provided by Nvidia are used and expanded to recognize lane markings, objects and the drivable free space around the vehicle. This enables various moving objects, such as cars and pedestrians, but also traffic lights and signs, to be recognized and classified. Due to the fusion with point clouds of the lidars, a transformation of the information from the camera image into world coordinates is possible.

Video Link: [Coming Soon]

Video description:

The different colors of the lane recognition indicate the position relative to the vehicle, the letter at the far end indicates the classification (B - border, S - solid line, D - dashed line). Object classes are identified by the color of their bounding box. For example, blue represents cars, yellow pedestrians and pink two-wheelers. Signs are framed in white, traffic lights are given the color of their detected light signal. With the clearance detection, the color of the line indicates the type of boundary. For example, green stands for the end of the road and blue for a potentially moving object.

Video description of the LDM:

The video shows excerpts / an excerpt from a measurement drive on the test corridor in October 2021. The objects detected by the front sensors (Ibeo lidar, radar, camera), as well as the point cloud of the front ouster and the camera image of the front camera are shown. The different colors of the objects indicate the classification.

In the course of highly automated driving, robust and precise knowledge of one's own system status and the global location is of fundamental importance.

There are various challenges along the route that make this task difficult for a single sensor system:

- GNSS shading from tall buildings or bridges

- Partly Missing lane markings

- Chaotic changes in the vehicle environment (e.g. in crowds on the Leipzig exhibition grounds)

- Changing light and weather conditions for year-round operation

- Poor environmental characteristics for environmental sensors in interurban operation

In order to counter these boundary conditions, information from lidar and camera sensors is used to localize the vehicle in addition to an RTK GNSS system and a magnetic field sensor to determine the direction of travel. Their signals are merged in a multi-stage filter system in order to achieve the most accurate and reliable estimate of the condition possible.

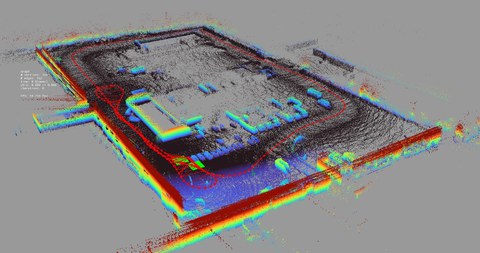

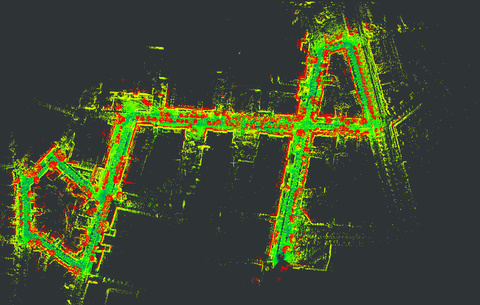

The following illustration shows an example of a map of the surroundings created with a 360 ° lidar while driving. Features such as edges and planes are extracted from each scan of the sensor and the relative movement of the vehicle is calculated from their shift between several points in time.

Point cloud map of the test field of the Professorship for Vehicle Mechatronics with driven trajectory (red)

Map of the TU campus created via Lidar-SLAM

Starting from a road-side unit on the respective control unit of the traffic light system, the vehicle receives the following protocols standardized according to ETSI:

- SPaTEM (Signal, Phase and Timing Extended Message)

- MAPEM (Map Extended Message).

This ensures that, among other things, the vehicle always receives information on the position of the signal transmitter relevant to it, its current signal status and the duration of the signal phase.

In addition to the direct optical detection of the signal transmitter, independent digital information is available for the driving decision.

Furthermore, the vehicle sends the protocol CAM (Cooperative Awareness Messages), which is also standardized according to ETSI, or CAM-R09 for public transport vehicles. This message is used to register and de-register the vehicle at the traffic light system.

Realizing an e/e-architecture fulfilling all requirements of automated vehicles poses a variety of challenges to the development process:

- the different (limited) interfaces and bus systems of the sensors and processing units

- the required bandwidths and low latencies

- the exchange of information across different domains

- the integration into an existing vehicle architecture

- the encapsulation of safety-relevant subsystems the robust connection of business-critical systems

- the limited electrical power d. Electrical systems

- the spatial separation of different EMC categories in the vehicle

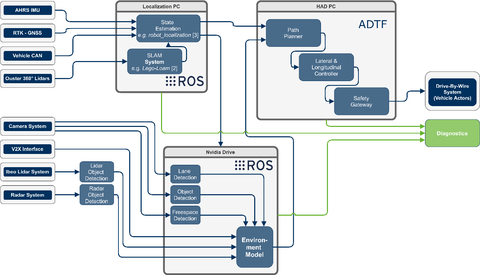

Simplified networking of the system components in the eCrafter

The picture shows the resulting E / E structure with the IT networking of the main components in the ABSOLUT vehicles. Comparable data sources with low data rates were combined (e.g. object data from sector lidars 1 -6, object data from radars), while data-intensive sources were routed directly to the processing units (image data from cameras 1-9, point clouds from lidars 7 and 8).

Via the CAN interfaces / gateways and Ethernet switches, on the one hand, the selective exchange of information between the communication subnets is enabled through appropriate mapping or active management, but on the other hand, targeted isolation is also carried out.

The video shows the physical integration of the electrical lines and the IT rack, which is the central installation location for the additional processing units in the vehicle and has a buffered power supply, in fast motion.

Extensive test steps are necessary for the safe commissioning of the vehicles in road traffic. In addition to general homologation tests carried out by DEKRA, such as braking and steering behavior, additional evidence of the safety of the systems and components used must be provided.

In order to be prepared for as many conceivable situations as possible, a risk analysis was carried out for the vehicles during the approval process. In this analysis, possible malfunctions are listed for all safety-relevant electrical and electronic systems based on the target function and categorized with regard to the severity of the hazard, probability of occurrence and controllability. From this, safety goals for the development as well as a safe state for the occurrence of the error are defined.

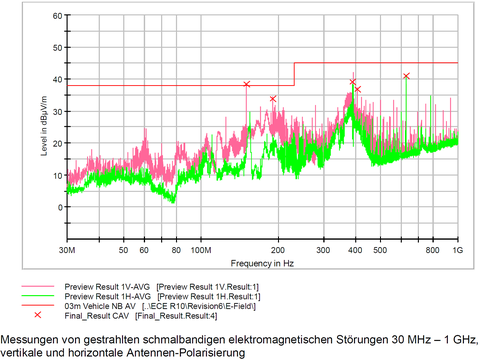

Since both vehicles have a significantly larger amount of electrical and electronic systems compared to the base, a renewed test of the electromagnetic compatibility (EMC) according to ECE R10 is necessary. This was carried out by SLG Testing and Certification GmbH and supported by the FTZ of the West Saxon University of Applied Sciences in Zwickau.

Frequency-dependent level curve as a result of the EMC test

VW eCrafter during the EMC test according to ECE R10

An accident data memory (UDS) was also a prerequisite for the approval of automated operation. As a kind of black box, this stores various vehicle parameters while driving, which are used to reconstruct traffic accidents and, in the event of traffic violations, to clarify whether the driver or the vehicle is responsible. In addition, the memory documents when and where a change from automated to manual operation and vice versa took place. Recorded parameters include: speed, position, time, driving mode (automated / manual), actuation of the controls.

After the DEKRA amendment report according to §21 StVO from 12.8. and the expert opinion to obtain an exemption according to §70 StVZO, as well as the issuance of the exemption by the LASuV (State Office for Road Construction and Transport), it is possible to approve the VW eCrafter and to move it manually in public road traffic. The exemption enables the developers to make changes to the vehicle as part of the testing without having to carry out a renewed acceptance of the entire vehicle. As a result, the development process can be made much more agile and optimizations can be implemented more quickly.