Monetary Measurement of Success of Lean-Production-Workshops with Suppliers

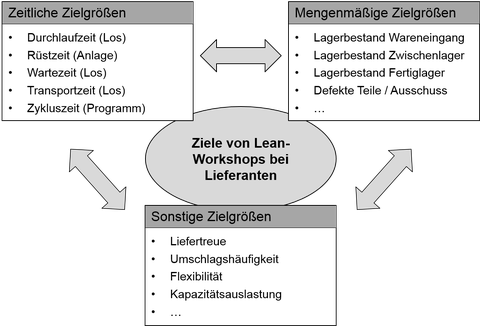

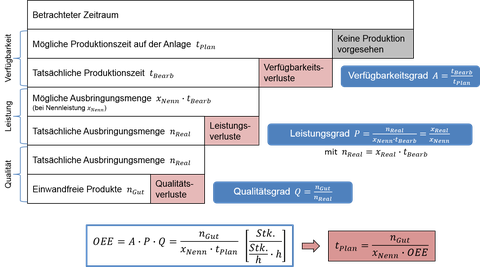

In order to meet the high requirements in terms of quality and flexibility in the automotive industry, ZF Friedrichshafen AG is supporting its suppliers by conducting lean production workshops as part of supplier development. Various lean production tools such as value stream mapping, setup optimization or 5S are being used in selected production lines here, which the supplier can then independently transfer to other areas. The improvements obtained as a result of a workshop are measured by means of the changes in selected performance indicators typical of the industry such as reject rate, throughput time or overall equipment effectiveness (OEE). Note that, while the performance indicators can be measured easily, they tend, due to their mostly technical nature, to permit statements about times and quantities rather than the related financial savings.

To develop a concept for monetary evaluation of the success of lean-production workshops, the relevant performance indicators were first selected and prioritized. With regard to these performance indicators, various approaches to monetary quantification were developed and, in close collaboration with the client, evaluated in respect of their suitability for use in practice. Special attention was paid to the interdependencies between the different performance indicators in order to avoid multiple identification of the improvements obtained. Finally, the selected evaluation approaches were implemented in an Excel tool and prepared in such a way as to enable the workshops to be evaluated directly on site and in collaboration with the supplier.

Partner

ZF Friedrichshafen AG, Bereich Lieferantenmanagement/ Lieferantenentwicklung

Duration

06/2013 - 10/2013

Involved Persons

Prof. Dr. Udo Buscher

Dipl.-Wi.-Ing. Gerhard Aust

Dipl.-Wi.-Ing. Ina Bräuer

Franz Ehm