Dec 16, 2025

TUD develops novel transfer system for liquid helium: DFG funds "TurboHeTra" project

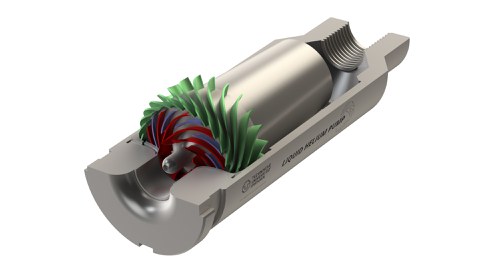

Schnittansicht der Heliumpumpe

The Schaufler Chair of Refrigeration, Cryogenics and Compressor Technology at the Institute of Power Engineering at TU Dresden is launching the new "TurboHeTra" research project. It is funded by the German Research Foundation (DFG) until December 2028. As part of the project, an innovative dual-flow transfer system for the loss-reduced supply of liquid helium (LHe) is being further developed. The aim of the research is to drastically reduce energy consumption and helium loss when filling cryogenic containers - a highly relevant topic for universities, large research institutions and industry-related laboratories worldwide.

At most universities and research facilities, liquid helium (LHe) is used at its standard boiling temperature of 4 K (-269 °C) for cooling tasks close to absolute zero. Numerous high-tech applications require liquid helium, including superconductivity, nuclear magnetic resonance spectroscopy, particle accelerators, as well as many areas of basic research and material characterization.

At the TUD, the Schaufler Chair operates the central helium liquefaction plant. Until now, cryogenic LHe transport containers have been filled via single-flow lines. However, this transfer process is highly lossy. These losses have to be compensated for by collecting the vaporized helium, purifying it and liquefying it again at great energy expense - a process that requires high double-digit megawatt hours of electricity every year.

The DFG-funded project follows on from a successful previous project. In this project, a functioning dual-flow prototype system has already been demonstrated and measured. A cryogenic turbopump transports the liquid helium, while the helium cold gas released in the target vessel is returned directly to the source reservoir via a second line. This reduces evaporation losses from 30 percent to four percent. The dual-flow transfer capacity was further developed as part of TurboHeTra. The system has been simplified to make it more compact and therefore easier to use elsewhere. Simulations were used to optimize the pump characteristics and pump efficiency, which also improved the LHe feed pump. A revised prototype was then produced, on which in-depth investigations were carried out into the cavitation and long-term behavior of the motor bearings. A system control to be developed should enable the system to be used in other helium plants with different operating conditions.

TurboHeTra has both scientific and industrial significance. By drastically reducing evaporation losses, existing helium liquefaction plants can increase their output by a third. The project thus contributes to better utilization of research infrastructure, reduces energy costs and supports the sustainable use of one of the most valuable cryogenic resources of all.

Contact:

Prof. Christoph Haberstroh

Schaufler Chair of Refrigeration, Cryogenics and Compressor Technology

Phone +49 351 463-33406

E-Mail: christoph.haberstroh@tu-dresden.de

Johannes Doll, Dipl.-Ing.

Schaufler Chair of Refrigeration, Cryogenics and Compressor Technology

Phone +49 351 463-32703

E-mail: johannes.doll@tu-dresden.de