Projekte

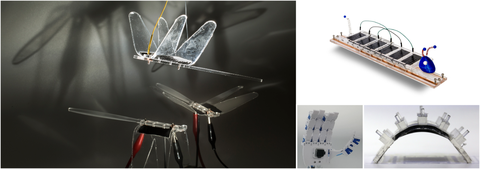

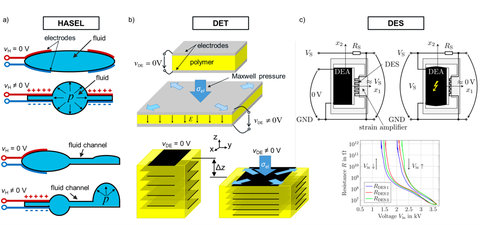

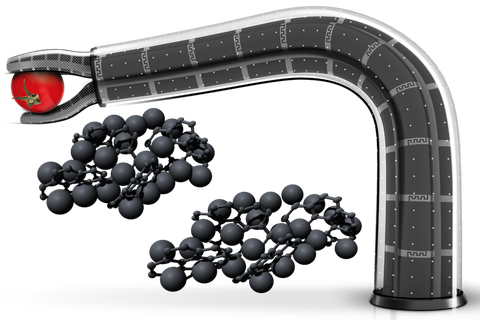

Herkömmliche Roboter bestehen in der Regel aus schweren und starren Komponenten wie Motoren, Getrieben und Gestängen, die aus hochdichten Materialien gefertigt sind. Obwohl sie komplexe Bewegungen und Prozesse ausführen können, sind sie in der Regel nicht in der Lage, Bewegungen auszuführen, die denen biologischer Vorbilder ähneln. Völlig weiche Roboter mit tierähnlichem Verhalten werden völlig neue Perspektiven und Anwendungen eröffnen. Im Projekt MEiTNER werden multifunktionale dielektrische Elastomere (DEs), sogenannte künstliche Muskeln, untersucht. Ziel ist es, diese dielektrischen Elastomere mit inhärenten Signalverarbeitungsfähigkeiten in Form einer dielektrischen Elastomerelektronik auszustatten, die nur aus Polymermaterialien und Kohlenstoff besteht. Dies wird eine völlig neue Klasse weicher Elektronik ermöglichen, mit der autonome, völlig weiche Roboter gesteuert werden können, ohne dass herkömmliche, starre, auf Silizium basierende Signalverarbeitung erforderlich sind.

Neuartige weiche DE-Elektronik wird auf dielektrischen Elastomermembranen unter Verwendung nachgiebiger Elektroden mit unterschiedlichen elektrischen Eigenschaften wie Widerstand, Kapazität und Perkolation integriert. Alle diese Komponenten werden nur aus Mischungen von Polymeren und leitfähigen Füllstoffen bestehen. Um die Funktionalität der entwickelten Prozesse und Teilkomponenten zu validieren, werden Untersuchungen zur Weiterentwicklung der weichen biomimetischen Robotik im Allgemeinen durchgeführt, um das Potenzial multifunktionaler DEs zu demonstrieren. Diese Roboterstrukturen werden auf nachgiebigen mechanischen Strukturen beruhen, in deren gesamte Struktur verteilte dielektrische Sensor-, Aktor- und Signalverarbeitungsknoten eingebettet sind.

Wir werden biomimetische Ansätze für verschiedene Aufgaben wie Fortbewegung, Flügelschlag oder Unterwasserantrieb und damit verbundene Schnittstellen zur Umwelt wie Richtungsreibung oder elektrostatische Strukturen untersuchen. In einer zweiten Forschungsrichtung werden wir die Schnittstelle zwischen Mensch und Maschine in der kollaborativen Robotik sowie in industriellen und medizinischen Anwendungen untersuchen. Die in FAB-1 entwickelten Technologien und DE-Elektronik- und Software-Design-Tools sollen genutzt werden, um die Aussichten für weiche, multifunktionale Strukturen zu untersuchen, die als nachgiebige Schnittstellen für Maschinenbediener, medizinische Produkte und industrielle Anwendungen wie weiche Robotergreifer dienen sollen.

Minimal-invasive Verfahren haben die moderne Medizin revolutioniert und spielen mit mehr als 2 Millionen laparoskopischen Operationen und 6 Millionen gastrointestinalen Endoskopien pro Jahr in Deutschland eine bedeutende Rolle. Im endoskopischen Bereich hat sich das Design der Geräte und des Zubehörs für diese Eingriffe in den letzten 40 Jahren praktisch nicht verändert. Im Bereich der Laparoskopie sind die Instrumente zur besseren Sterilisierbarkeit als starre Metallschäfte ohne Gelenke ausgeführt. Bestimmte Blickwinkel auf das Operationsgeschehen können dadurch nur sehr schwer bzw. in manchen Fällen gar nicht eingestellt werden. Durch die fehlende elektronische Ansteuerung ist es derzeit auch nicht möglich, die Instrumente in moderne Assistenzsysteme („cybermedical systems“) einzubinden. Eine Alternative hierzu stellen aktuell nur große stationäre Robotersysteme (wie z.B. der Da Vinci Roboter) dar, welche zwar bewegliche Gelenke aufweisen, jedoch mit hohen Anschaffungs-, Betriebs- und Aufbereitungskosten verbunden sind und somit von kleineren Kliniken nicht wirtschaftlich betrieben werden können. An diesem Punkt setzt das Vorhaben EndoSMART an: Das Entwicklungsziel sind robotische Einweghandgeräte, die in digitale Assistenzsysteme integriert werden und so die Lücke zwischen nicht zeitgemäßen, manuellen Instrumenten und teuren robotischen Großgeräten schließen können.

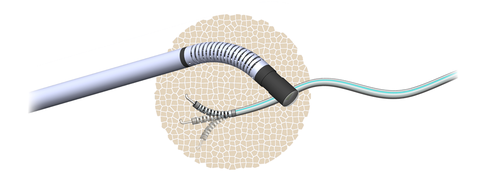

Die Aktorbasis für diese Systeme bilden Drähte aus der Formgedächtnislegierung (engl. Shape Memory Alloys – SMAs) Nitinol. Sie bieten aufgrund ihrer Leistungsfähigkeit und ihrer hervorragenden Skalierbarkeit ein enormes Potenzial als Aktorplattform für laparoskopische und endoskopische Einweginstrumente. Im Verbundprojekt „NGScopes“ konnte bereits ein Demonstrator entwickelt werden, welcher die grundsätzliche Eignung von SMA-Aktoren für den Einsatz in derartigen Instrumenten aufzeigte. Im Rahmen des aktuellen Forschungsvorhabens „EndoSMART“ werden nun der gegenwärtige Entwicklungsstand aufgegriffen und weitere bzw. offene Probleme adressiert. Diese sind teils von grundlegender Natur und beinhalten beispielsweise die Implementierung eines Systems zum Wärmemanagement, sowie die Skalierung der Aktorplattform für den Einsatz in laparoskopischen Werkzeugen. Zentrale Fragestellungen hierfür bilden die Ausgestaltung eines biegeweichen, aber drucksteifen Miniaturgelenks sowie die anforderungsspezifische Anpassung der Aktorkraft. Um das Innovationspotenzial der SMA-betriebenen Instrumente zu verdeutlichen, spielt das Nutzerinterface eine herausragende Rolle. Hier sollen erste praxisrelevante digitale Assistenzfunktionen erforscht und anschließend hard- und softwareseitig implementiert und durch Anwender getestet werden.

Next Generation Endoscopy des EKFZ (Else Kröner Fresenius Center for Digital Health)

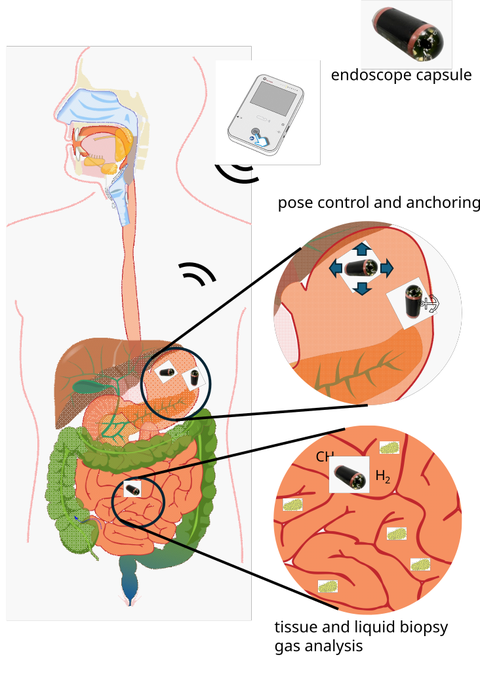

In Deutschland werden jedes Jahr rund 6 Millionen Endoskopien durchgeführt. Sie spielen eine zentrale Rolle bei der Diagnose und Behandlung von Krebs und anderen Erkrankungen des Magen-Darm-Trakts. Kapselendoskope sind eine attraktive Alternative zu herkömmlichen Diagnoseverfahren, da sie eine Diagnose des gesamten Gastrointestinaltrakts bei geringerem Unbehagen oder Verletzungsrisiko für den Patienten ermöglichen. Darüber hinaus können Bereiche des Dünndarms erreicht werden, die mit traditioneller Endoskopie nicht zugänglich sind. Kapselendoskope haben das Potenzial, die Arbeitsbelastung von Gastroenterologen erheblich zu reduzieren. Allerdings bleibt der Funktionsumfang noch weit hinter dem der etablierten Endoskope zurück.

Unsere Vision ist es, erweiterte Funktionen für Kapselendoskope zu entwickeln, die adaptive Verankerungsmechanismen, die Möglichkeit zur Entnahme von Gewebe- und Flüssigbiopsien und die In-vivo-Mikrobiomanalyse mit Gassensoren umfassen. Darüber hinaus muss eine sichere bidirektionale Kommunikation durch den Körper mit hohen Datenraten gewährleistet sein. Eine magnetische Kapsellagekontrolle wird die präzise Betätigung der entwickelten Mechanismen ermöglichen.

Bislang haben wir einen funktionierenden Aufbau eines Kapselmoduls für die Flüssigbiopsie demonstriert. Wir haben Antriebskonzepte für die Gewebebiopsie und die Verankerung entwickelt. Zum Schutz des Gassensors wurde eine flüssigkeitsabweisende und gasdurchlässige Membran in ein Kapselmodul integriert. In einem Laboraufbau ist der Sensor in der Lage, Signale für den Wasserstoff- und Methangehalt mit vielversprechender Genauigkeit zu erfassen. In einem Testaufbau haben wir die bidirektionale Kommunikation demonstriert und haben die magnetische Kapsellagesteuerung auf einer Wasseroberfläche gezeigt.

Das Verbundprojekt "Aktive intelligente Kapselendoskopie" wird von einem Konsortium aus Lehrstühlen der TU Dresden und Industriepartnern aus Deutschland durchgeführt. Es ist Teil des vom BMFTR geförderten Zukunftsclusters “SEMECO” (Secure medical microsystems and communications).

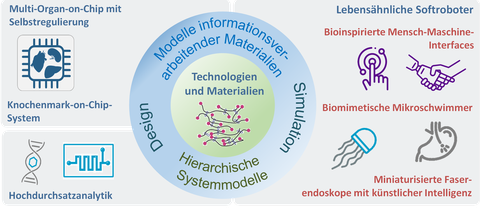

Die Nachwuchsforschungsgruppe MultiMOD beschäftigt sich mit den Grundlagen eines Schaltkreis- und Informationsverarbeitungskonzeptes auf Basis smarter Materialien. Dies ermöglicht die direkte Verarbeitung verschiedener physikalischer, chemischer und biologischer Informationsträger in unserer Umwelt, ohne dass elektronische Komponenten benötigt werden. Diese Schaltkreise ermöglichen die Integration von viel mehr Funktionen auf Chipebene, einschließlich Informationsverarbeitung, Energieversorgung, Sensorik und Aktorik. Sie sind äußerst energieeffizient und benötigen nur einen Bruchteil der Ressourcen, die in herkömmlichen mikroelektronischen Systemen verwendet werden, und sind in hohem Maße recycelbar.

Die Nachwuchsforschungsgruppe konzentriert sich auf drei spezifische Anwendungen in den Biowissenschaften, die in hohem Maße von den Fähigkeiten dieser multimodalen Schaltkreise profitieren können: Multi-Organ-on-Chip-Systeme mit komplexen chemisch-biologischen Regulationsmechanismen, multimodale Schaltkreise für die Krebsfrüherkennung und mikrorobotische Systeme mit naturgetreuen Fähigkeiten für den Einsatz als Operationsroboter.

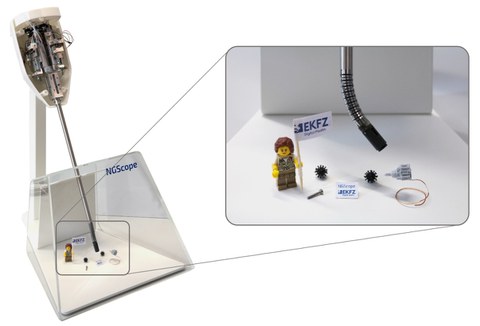

In dem Verbundprojekt NGScopes wird eine Prinziplösung für eine universelle und skalierbare Aktorplattform auf der Basis von Formgedächtnislegierungen (engl. shape memory alloys – SMAs) für eine neue Generation von Endoskopen und endoskopischen Werkzeugen entwickelt und auf ihre Eignung für den Einsatz in medizinischen Instrumenten hin untersucht.

In ersten Arbeitsschritten des Projekts wurden zunächst die thermischen Belastungen endoskopischer Instrumente ermittelt. Die gewonnenen Erkenntnisse bildeten wichtige Basisparameter für die spätere Auswahl der Konstruktionswerkstoffe und wurden unter dem Titel „Temperature profile and residual heat of monopolar laparoscopic and endoscopic dissection instruments“ publiziert. Für die Auswahl der Aktoren und die Auslegung der Mechanik ist eine grundlegende Charakterisierung der Material- und Aktoreigenschaften der SMA-Drähte essenziell. Hierfür wurde ein multisensorischer Versuchsstand entwickelt und in Betrieb genommen. Anschließend konnte ein erstes Funktionsmuster mit separatem Nutzerinterface und Kamera erfolgreich in Betrieb genommen werden. Aufgrund der geringeren technologischen Hürden orientiert sich der erste Demonstrator an starren endoskopischen Instrumenten (auch „Laparoskop“).

© TU Dresden

© TU Dresden

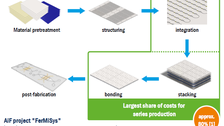

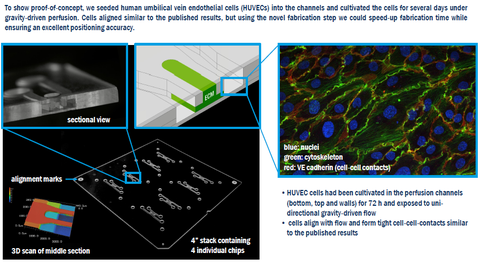

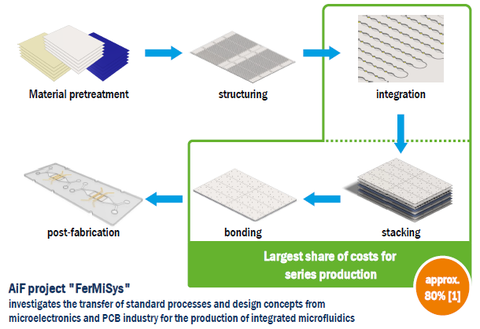

Im vorliegenden Forschungsprojekt soll die Übertragung von Standardprozessen und Designkonzepten der Mikroelektronik- und Leiterplattenindustrie für die Fertigung hochintegrierter, hybrider Mikrofluidik-Systeme untersucht werden. Der Schwerpunkt des Forschungsvorhabens liegt dabei auf der Entwicklung und Optimierung einer Fertigungstechnologie solcher Systeme.

Konkret soll ein bestehendes Fertigungsverfahren für mehrlagige mikrofluidische Prototypen anhand in der Mikroelektronik etablierter Produktionsprozesse und –equipment für mehrlagige keramische Schaltungen skaliert und eine volumenunabhängige Prozesskette entwickelt werden. Dadurch können Design und Material über den gesamten Skalierungsprozess hinweg identisch bleiben und ein nahtloser Transfer vom Prototypen zum Produkt gewährleistet werden.

Betrachtet man Mikrofluidik-Systeme (MFSs) als „fluidische Leiterplatten,“ in der die mikrofluidischen Kanäle die Leiterbahnen repräsentieren, ist es konsequent, die in der Leiterplattenindustrie seit vielen Jahren etablierten Fertigungsprozesse zu adaptieren und auf die Herstellung von MFs für die medizinisch-biologische Forschung anzuwenden. Dazu sollen etablierte LTCC-Teilprozessabläufe (Low Temperature Cofired Ceramic) sowie Equipment für deren Fertigung übernommen und an die für polymere hochintegrierte MFSs verwendeten Materialien angepasst werden. Die aktiven Systemkomponenten und Substrate sollen dabei mittels etablierter Verfahren mikrostrukturiert, ausgerichtet, gestapelt und gefügt werden. Zum Erhalt der strukturellen Integrität der Kavitäten und Kanäle ist eine Verringerung der Prozesstemperaturen notwendig. Um dies zu erreichen, sollen die Substrate mit geeigneten Verfahren vorbehandelt (Haftvermittlerauftrag, VUV-Bestrahlung) werden. Am Projektende soll eine vollständig aufeinander abgestimmte Prozesskette entstehen, die eine flexible Fertigung hochkomplexer hybrider Mikrofluidik-Systeme bei geringen Temperaturen ermöglicht.

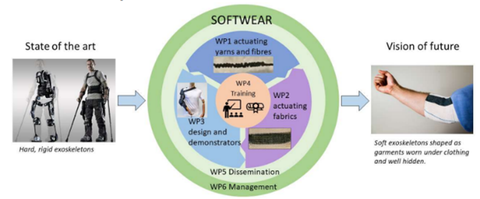

Das Marie-Skłodowska-Curie-Doktorandennetzwerk SOFTWEAR ist ein hochgradig interdisziplinäres Doktorandennetzwerk im aufstrebenden und schnell wachsenden Bereich der Wearables, mit einem einzigartigen Schwerpunkt auf weichen Aktoren für Wearables und Exoskelette. Das Hauptziel von SOFTWEAR ist es, junge Forscher in der multidisziplinären Wissenschaft der weichen Aktuatoren für die Integration in Wearables und Augmentierung von Textilien auszubilden. Dies wird erreicht, indem Chemie, Physik, Mechanik, Elektronik, Textiltechnologie, Design, Mensch-Technik-Interaktion und Ethik in einer wirklich interdisziplinären Weise zusammengeführt werden, während gleichzeitig wesentliche Fähigkeiten in den Bereichen Ethik, Produktentwicklung, geistiges Eigentum und industrielle Umsetzung vermittelt werden, was einen einzigartigen Mehrwert für die Laufbahn der Forscher darstellt. Erreicht wird dieses ehrgeizige Ziel durch eine praktische Ausbildung in innovativen Forschungsprojekten, bei denen eine über den Stand der Technik hinausgehende weiche Antriebstechnologie entwickelt und in aktive Kleidungsstücke und weiche Exoskelette integriert wird. Dies wird bei führenden akademischen Gruppen und durch Eintauchen in angewandte Projekte bei den Industriepartnern durchgeführt. SOFTWEAR wird somit Europa mit hochqualifizierten Forschern auf dem neu entstehenden Gebiet der Wearables versorgen, die sich auf die Integration von Aktuatoren konzentrieren. Dies wird Europa in eine weltweit führende Position in diesem Bereich bringen und europäische Unternehmen mit hochqualifizierten Arbeitskräften für weiche Aktoren und fortschrittliche intelligente Textilien versorgen.

Dielektrische Elastomerschalter (DES) ermöglichen die Einbettung einiger Signalverarbeitungsfunktionen in weiche Strukturen. Mit Hilfe von DESs soll ein verteiltes und miniaturisiertes Netzwerk von weichen DE-Aktor-, Sensor- und Signalverarbeitungsknoten in einer vollständig weichen Struktur entwickelt werden, das fortschrittliche tragbare Strukturen mit reflexiver Funktionalität ermöglicht. Sie erkennen selbständig die Betätigung und kritische Auslenkung von Gliedmaßen und treffen somit autonome Entscheidungen.

Die TU Dresden und die Technische Universität München haben sich zum Forschungszentrum 6G-Life zusammengeschlossen, um Spitzenforschung für zukünftige 6G-Kommunikationsnetze mit Fokus auf Mensch-Maschine-Kollaboration voranzutreiben. Der Zusammenschluss der beiden Exzellenzuniversitäten bündelt ihre weltweit führenden Vorarbeiten im Bereich des taktilen Internets im Exzellenzcluster CeTI, 5G-Kommunikationsnetze, Quantenkommunikation, Post-Shannon-Theorie, Methoden der Künstlichen Intelligenz sowie flexible Hard- und Softwareplattformen.

Es wird ein softrobotischer Kontinuumsroboter mit kinästhetischem Feedback-System und taktiler Feedback-Einheit an den Effektoren entwickelt. Er verfügt über ein Repertoire an automatischen und adaptiven Bewegungsmustern, was ihm Selbstführungs- und Pfadfindungseigenschaften verleiht, und über einen Tastsinn, was ihm ermöglicht, die mechanischen Eigenschaften und die Temperatur des Operationsfeldes sowie die Gegenwart bestimmter chemischer Substanzen zu ertasten.

Schwerpunktprogramme

Kollaborative Multi-Aktor-Systeme werden zukünftig wichtige Komponenten für visionäre Technologien sein, beispielsweise in der Robotik, bei medizinischen Geräten und fortschrittlichen Benutzerschnittstellen. Der potenzielle Einsatzbereich solcher Geräte reicht von der Nanoskala, wo sie in einem Bereich arbeiten, in dem viele Phänomene ihren Ursprung haben, bis zur Mikro- und Makroskala. In konzeptioneller Hinsicht unterscheiden sie sich in den verschiedenen Größenordnungen erheblich. Je größer sie werden, desto mehr nähern sich die technischen Anforderungen den menschlichen Fähigkeiten an. Sie sollen in der Lage sein, selbständig komplexe Bewegungsabläufe und Aufgaben zu realisieren, ihre Umwelt wahrzunehmen und situationsgerecht autonom zu handeln. Entsprechend leistungsfähige robotergestützte Multi-Aktor-Sensor-Strukturen gehören zu den bedeutenden, kaum gelösten technischen Herausforderungen, die bei kleinen Systemen durch die funktionalen, technologischen und integrativen Zwänge der Größenbegrenzung noch erheblich verstärkt werden. Erforderlich sind Sensoren mit den notwendigen Empfindlichkeiten, geeignete Aktoren, Hard- und Software zur Steuerung oder Regelung der Informationsverarbeitung sowie Strategien zur Montage und Systemintegration. Dies führt z. B. bei konventionellen starren Robotern zwangsläufig zu einer deutlichen Erhöhung der Komplexität von Hard- und Software und einer entsprechenden Verschlechterung der Energie- und Nachhaltigkeitsbilanz, da noch mehr informationsverarbeitende Elektronik, Sensoren und Aktoren benötigt werden. In diesem Projekt sollen vernetzte, verteilte HASEL-DET-DES-Aktor-Module entwickelt werden, die neuartige Methoden erfordern. Der klassische Prozess der Produktentwicklung und -optimierung über mehrere Zyklen von Design, Prototyping und messtechnischen Untersuchungen ist nicht mehr geeignet. Die leistungsfähige simulationsbasierte Entwurfsmethodik anhand eines virtuellen hierarischen Entwurfs soll daher hier herangezogen werden. Basiseinheiten, bestehend aus HASEL, DET oder DES, werden synergetisch zu Einzelaktormodulen kombiniert, die ihrerseits Submodule für die kooperative elastomere Multi-Aktuator-Plattform (CALMAR) darstellen, die verschiedenen Funktionalitäten wie kooperatives Verhalten, Multi-Level-Aktivierung, Multi-Stabilität und inhärentes Erfassen interner und externer Stimuli realisieren können. Der Einfluss der Parameter auf das Systemverhalten kann dann effizient simuliert werden, um das System für ein gewünschtes Verhalten zu optimieren. Eine ganzheitliche multivariable Regelstrategie bietet minimale Regeleingaben für ein wohldefiniertes Systemverhalten. Mit Hilfe einer zu entwickelnden modellbasierten Toolbox kann aus den verfügbaren HASEL-DES-DEA-Basiseinheiten und Grundfunktionen die optimale Konfiguration für die jeweilige Anwendung zusammengestellt werden. Abschließend wird die geplante kooperative Multi-Aktor-Plattform mittels additiver Fertigung realisiert und im Detail erforscht.

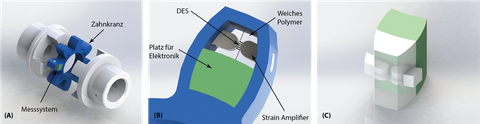

Kupplungen sind Maschinenelemente, deren primäre Funktion darin besteht, eine Leistungsübertragung zwischen zwei Wellen durch eine mechanische Verbindung zu ermöglichen. Den formschlüssigen drehelastischen Kupplungen wird in der Antriebstechnik eine hohe Bedeutsamkeit zugesprochen, da sie einerseits konstruktiv vergleichsweise einfach ausgeführt und somit preisgünstig sind und andererseits aufgrund der Drehnachgiebigkeit kritische Drehmomentenstöße mildern sowie systembedingte dynamische Schwingungen dämpfen können. In diesem Projekt sollen elastische Kupplungen, wie Zahnkranzkupplung und Keilpaketkupplungen mit Sensoren ausgestattet werden, um Drehmomente und Kräfte während der Laufzeit im Einsatz zu bestimmen. Solche Kupplungen verfügen über elastische Elastomerelemente zum Ausgleich axialem und radialem Versatz und zur Aufnahme von Drehmomentenstößen. Die Sensoren sollen direkt in die nachgiebigen Elastomerelementen untergebracht werden und diese sowohl geometrisch, als auch mechanisch nach außen, nicht, oder nur so wenige, wie möglich, verändern. Aus diesem Grund sollen im beantragten Projekt nachgiebige, integrierbare Sensorsystemen, inklusive der notwendigen Auswertungs- und Kommunikationselektronik entwickelt werden. Speziell sollen hier piezoresistive und kapazitive dielektrische Elastomersensoren entwickelt und integriert werden. Die unter Belastung zu erwartenden Verformungen in den Elastomerelementen liegen im Prozent-Bereich und sind somit nur schwer mit konventionellen Messsystemen, wie bspw. Dehnmessstreifen zu erfassen. Vielmehr scheint er vorteilhabt ein Messsystem zu entwickeln, dessen mechanische Eigenschaften, denen des Elastomerelement ähnlich sind. Aus diesem Grund sollen im Projekt dielektrische Elastomer als Sensoren verwendet werden.

Das Projektteam besteht aus drei Arbeitsgruppen, die ihr jeweilige Expertise in das Projekt einbringen. Die Arbeitsgruppe Schlecht am Institut für Maschinenelemente und Maschinenkonstruktion (IMM) beschäftigt sich mit der Untersuchung und Bestimmung relevanter Systemparameter an realen Kupplungssystemen und stellt notwendige Daten zur Verfügung, die notwendig sind, damit die Arbeitsgruppe Wallmersperger am Institut für Festkörpermechanik (IFKM) mit der Simulation der elastischen Komponenten und des Gesamtsystems beschäftigen kann. Die gewonnenen Daten dienen der Arbeitsgruppe Henke, MEiTNER Nachwuchsforschergruppe am Institut für Halbleiter und Mikrosysteme (IHM), zum Entwurf und zur Auslegung der einzelnen Sensorelemente und Auswerteelektronik. Die vom IHM aufgebauten Sensordemonstratoren werden anschließend in reale Kupplungen integriert, deren Verhalten wird am IFKM simuliert und von IMM unter realen Bedingungen auf entsprechenden Prüfständen getestet.

Projekt BROADCAST schafft eine neue Klasse weicher, biomimetischer Systeme, die mit der Umgebung in einer sicheren, bio-inspirierten Weise interagieren können. Der Ansatz basiert auf wichtigen Forschritten in der Produktionstechnik von Schaltkreisen auf Basis dielektrischer Elastomere (DE), neuen weichen elektronischen Materialien und neuen Ansätzen bei der Signalverarbeitung. BROADCAST untersucht multifunktionale DE, die robotische Strukturen steuern auf Basis bioinspirierter elektromechanischer Strategien wie zentraler Mustergeneratoren, auronomer Perestalsis und Lokomotion und anderer. Dies erfordert neue Materialien für flexible Elektroden und Sensoren, die zugeschnittene elektrische und elektromechanische Eigenschaften wie Elastizitätsmodul, Leitfähigkeit und Piezoresitivität liefern.

Abgeschlossene Projekte

In den 1990er Jahren entstand das Konzept des Lab-on-a-Chip (LoC), um die Fluidverarbeitung auf einem einzigen Chip zu integrieren. Anfangs für grundlegende Tests genutzt, hat sich die Mikrofluidik weiterentwickelt und dabei von Point-of-Care (PoC) und Next Generation Sequencing profitiert. Programmierbare LoC und kanalbasierte LoC dominieren, wobei die Mikropneumatik vielversprechend ist. Das chemomechanische Mikrofluidik-Konzept an der TU Dresden nutzt Ventilschaltungen auf dem Chip, um externe Steuerungen zu reduzieren und Entscheidungsfunktionalitäten basierend auf chemischen Informationen zu bieten.

Die automatisierte Einzelzell-Probenpräparation für molekulare Analysen stellt eine Herausforderung dar. Aktuelle Ansätze weisen Lücken in der Abdeckung von Arbeitsabläufen und der Erfassungseffizienz auf. Es gibt bisher keine kommerzielle Lösung, die den Anforderungen an die Einzelzell-Probenpräparation hinsichtlich Durchsatz, Erfassungseffizienz und Populationsqualität gerecht wird.

Das Projekt TransIC zielt darauf ab, die Leistungsfähigkeit eines chemofluidischen Schaltkreiskonzepts zu bewerten, mit Fokus auf der Einzelzell-Probenpräparation für die Diagnose von AML (Akute Myeloische Leukämie). Die Technologie strebt einen Knotenpunkt von 50 µm für automatisierte Schaltkreise und 15 µm für zellbezogene Strukturen an.

Die Automatisierung des Designs wird entscheidend für Schaltkreise mit Tausenden von Komponenten sein. Passive und aktive Komponenten werden charakterisiert, und Simulationsmodelle werden genutzt, um einen mikrofluidischen Arbeitsablauf zu entwerfen, der dann experimentell verifiziert wird.

Materialien für integrierte Schaltkreiskomponenten werden hinsichtlich Verarbeitbarkeit, Haltbarkeit und Umweltaspekten ausgewählt.

Anwendungsbezogen wird die Funktionalität der Schaltkreise unter Laborbedingungen demonstriert, um Sensitivität, Reproduzierbarkeit und Robustheit im Vergleich zu kommerziellen Kits und Chips sicherzustellen.

Parallel zur erreichten Miniaturisierung wird der Nachweis von etwa 600 Reaktionskaskaden für die AML-Probenpräparation und Probennachverarbeitung an einem 15 µm Knotenpunkt erbracht.

Die Forschungsarbeit zeigt das Potenzial mikrofluidischer Ansätze zur Verbesserung der individuellen Therapie und Überwachung von Blutkrebskrankheiten wie die AML. Ein modifiziertes Pachinko-Design lieferte vielversprechende Ergebnisse für die Isolierung von Leukämiezellen, mit der Option, bestimmte Zielzellen schonend aus Fangstrukturen zu lösen und für weitere Einzelzellanalysen bereitzustellen. Diese Fähigkeit ist mit vorhandenen kommerziellen Plattformen nicht erreichbar. Daher besteht die Möglichkeit, die individuelle Therapie für Patienten mit AML und anderen Leukämie- und Lymphomerkrankungen zu optimieren. In den letzten Jahren wurden teure neue Immuntherapien entwickelt, deren Wirksamkeit im Vorfeld individuell überprüft werden muss. Diese neue Technologie könnte helfen, auf Einzelzellebene zu bestimmen, wie effektiv entartete Vorläuferzellen bei der AML durch die Therapie angegriffen und eliminiert werden können.

© TU Dresden

© TU Dresden

© TU Dresden

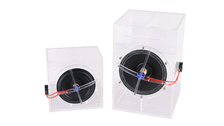

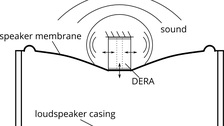

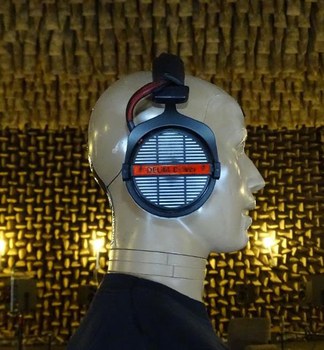

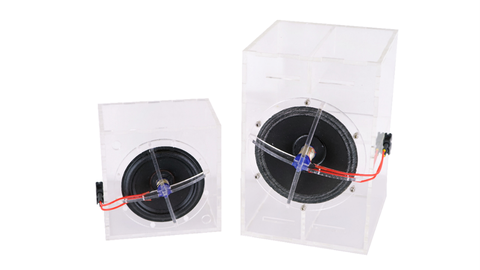

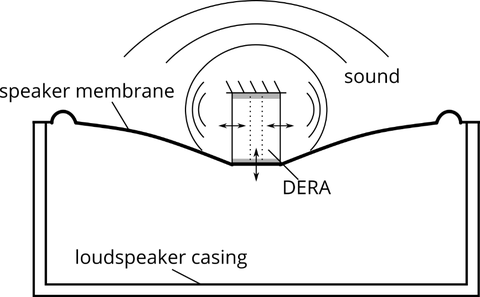

Am Lehrstuhl für Mikrosystemtechnik erfolgt die Entwicklung von dynamischen Systemen auf Grundlage dielektrischer Elastomere. Dabei handelt es sich um dünne beidseitig mit dehnbaren Elektroden beschichtete Elastomerfilme die sich bei anlegen einer Spannung verformen.

Daraus können künstliche Muskeln erzeugt werden die dynamisch angeregt sich als Kraft und Auslenkungsquellen z. B. für dir Realisierung von Lautsprechern eignen.

Auf dieser Grundlage wurden bereits neuartige Kopfhörertreiber mittels dielektrischer Elastomer unimorph Membrane (DEUM-Driver) als auch Lautsprecher mit dielektrischem elastomer Rollenantrieb (DERA-Lautsprecher) entwickelt und vorgestellt. Diese Wurden jeweils mit dem ersten Preis bei der EuroEAP-Society Challenge ausgezeichnet.

Im Vergleich zu konventionellen Elektrodynamischen bieten sie deutlich reduzierteres Gewicht und Bauraumbedarf und einen erheblich gesteigerten Wirkungsgrad. Darüber hinaus sind sie robust und können aus günstigen Ausgangsmaterialien ohne den Einsatz von Seltenerden, Piezokeramiken oder gar ferroelektrischer Metalle hergestellt werden.

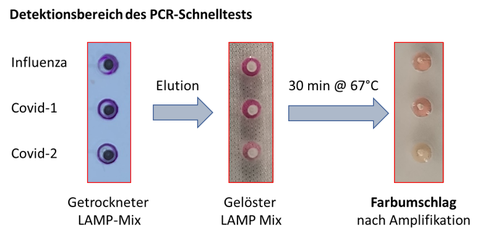

Die Nachwuchsforschungsgruppe CoVGuard hat das Ziel, einen PCR-Schnelltest für Covid-19 und andere Erreger zu entwickeln. Dieser soll die Einfachheit und gute Verfügbarkeit von Antigen-Tests mit der hohen Sensitivität und Zuverlässigkeit von PCR-Tests kombinieren, sodass für künftige Pandemien ein effizientes Mittel für die flächendeckende Diagnose zur Verfügung steht.

Die Entwicklung des PCR-Schnelltests basiert auf dem Konzept eines mikrofluidischen Schaltkreises, der Patientenproben autonom prozessiert und mittels isothermaler Amplifikation Erreger nachweist. Hierfür arbeiten die Forschenden an den Schaltkreisdesigns, Steuerelementen auf Basis smarter Materialien, sowie den biochemischen Nachweismethoden.

An der Forschung sind das Institut für Halbleiter- und Mikrosystemtechnik, das Institut für Klinische Chemie und Laboratoriumsmedizin sowie das Institut für Mikrobiologie und Virologie der TU Dresden bzw. des Universitätsklinikums Dresden beteiligt. Diese Maßnahme wird durch den Europäischen Sozialfonds als Teil der Reaktion der EU auf die Covid-19 Pandemie finanziert und hat die Laufzeit 01.01.2022-31.12.2022.