Modular Process Plants

In the process industry, raw materials are extracted and processed using chemical and physical processes to produce, for example, basic and specialty chemicals, medical drug substances or food. A constant challenge is the adaptation to changing boundary conditions, be it the discontinuation of raw materials, a fluctuating demand for products or new technologies with simultaneously high requirements for sustainability, product quality and safety.

Produktflexibilität: BIONTAINER [1]

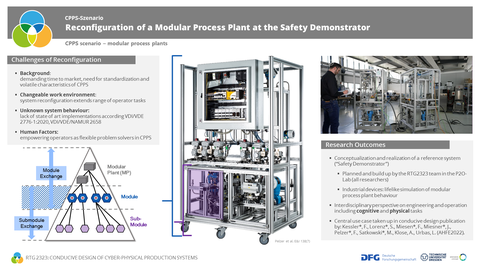

Modular plants are an important solution for increasing the changeability of plants in the process industry, that is the ability to adapt to new requirements without large investments. Modular plants are composed of individual highly automated modules from a module pool, which can be freely combined with each other.

Ortsflexibilität: BIOFABRIK [2]

The standardized interfaces, tools and methods required for this have now reached such a high level of maturity that the first modular plants are being piloted and implemented in the process industry.

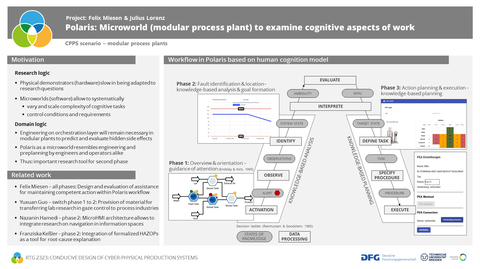

The dramatic acceleration of the engineering processes from product idea to production that accompanies the increased changeability raises extensive questions at the interfaces to the people who bear responsibility in these systems:

- What competencies do engineers and operators need to manage the demands of changeable modular plants well and without long-term health effects?

- How shall we design modular systems to be conducive to acquisition and maintenance of these competencies?

- What competencies do engineers need to perform these design tasks?

- How shall workflows and methods be specifically designed so that flexibility and safety do not contradict each other?

We are addressing these and other questions of human-technology cooperation in modular plants in several doctoral projects in the research program of the Research Training Group CD-CPPS. In cooperation with the Process-to-Order Lab and the Chair of Process Control Systems of the TU Dresden we have developed two demonstrators on which systematic empirical investigations can be carried out in an almost industrial environment with realistic tasks. The following posters give an overview of the two research environments.

© Felix Miesen / Julius Lorenz

© Florian Pelzer / Anselm Klose / Lucas Vogt

References

[1] https://www.pharma-food.de/markt/biontech-stellt-modulare-mrna-produktionsanlagen-vor-244.html

[2] https://biofabrik.com/de/wastx-plastic/