Generic thermal-hydraulic and physicochemical analysis for implementing an ATHLET module to simulate thermohydraulic consequences of zinc borate precipitation in the PWR core (joint research project AZora)

Sub-Project:

Laboratory experiments to model the crystallization and deposition behavior as well as heat transfer properties of zinc borates

Motivation:

In the case of a loss-of-coolant accident in a PWR, corrosion of hot-dip galvanized inventory like tread gratings and support grids of sump strainers in boric acid-containing coolant can be expected, possibly resulting in subsequent depositions of formed zinc borates as sparingly soluble corrosion products in hot zones of the PWR reactor core.

Objectives:

The main goal of the project was to generate data and correlations on the following topics based on generic experimental investigations:

- Solubility and crystallization behavior of formed zinc borates in the coolant

- Parameter dependent deposition rates of zinc borates on cladding tube surfaces as layers or as mobile particles in the heated coolant

- Dependence of the thermal conductivity of zinc borate layers on cladding tube surfaces on the conditions of formation (temperatures, zinc concentrations, flow conditions)

- Removal of zinc ions from the coolant using ion exchangers

The resulting data and correlations were used by the project partner GRS as a basis for the modeling and computer-aided simulation of thermal-hydraulic effects caused by zinc borate depositions in the reactor core. In such way, it should be possible in the future to receive a more accurate and reliable analysis of thermo-hydraulic consequences of zinc borate depositions in the reactor core for various LOCA scenarios. Furthermore, the comparison of the LOCA scenarios can be improved with respect to safety-related questions.

Methods and results:

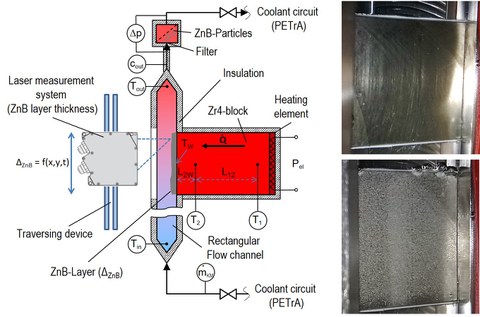

Left: Basic structure of the measuring cell with heated zircaloy block for the determination of parameter-dependent zinc borate deposition rates and thermal conductivities of grown zinc borate layers on hot surfaces of cladding tubes

Right: Surface of the Zr4 unit before and after a zinc borate precipitation experiment

The results of the experiments on the time-dependent growth of zinc borate layers showed constant layer growth rates in the range of 2...7 μm/h depending on the thermal power transferred via the Zircaloy surface, the coolant temperature and the zinc borate concentration in the coolant. Thus, corresponding empirical correlations could be established for these parameters. In contrast, the flow velocity of the coolant had no significant influence on the layer growth rate in the range investigated. The arithmetic mean roughness value of the zinc borate layers was in the range 0.13...0.34 mm.

The experimentally determined thermal conductivity of the zinc borate layers was in the range of 3.7...5.7 W/(m K) and thus far below the thermal conductivity of zinc borate of 26 W/(m K) stated in the literature due to the porous structure of the zinc borate layers. This emphasizes the importance of the experimental investigations, especially as the thermal conductivity of the zinc borate layers is well below the thermal conductivity of Zircaloy-4 and the zinc borate layers can therefore represent a significant barrier for the transfer of decay heat from the fuel rod into the coolant.

Within the experimental study on zinc removal from the coolant using available coolant cleaning systems, it was shown that typical cation exchange resins used in coolant cleaning systems of PWR plants are suitable for the removal of Zn2+ ions from the coolant. The ion exchange capacity is approx. 0.1 kg zinc per kg resin. The experiments using downscaled ion exchange columns have further shown that the zinc concentration in the coolant can be reduced by at least 90 % by passing the coolant through the column once. A demonstration experiment with simultaneous zinc release, precipitation and removal showed that an efficient removal of zinc ions from the coolant is also possible under the conditions of a specific LOCA scenario and that zinc borate deposits in core channels can be effectively prevented using the coolant cleaning system.

As a result of this study, an efficient method for preventing the thermo-hydraulic consequences of zinc borate depositions on PWR core structures has been developed and validated using existing PWR power plant technology.

Publications:

U. Harm, M. Wiezorek, H. Kryk, U. Hampel

LOCA Scenario-Related Zinc Borate Precipitation Studies at Lab Scale

Proceedings of the Annual Meeting on Nuclear Technology (AMNT 2019), Berlin 2019

W. Kästner, S. Alt, A. Seeliger, F. Zacharias, U. Harm, R. Illgen, U. Hampel, H. Kryk

Modelling thermal-hydraulic effects of zinc borate deposits in the PWR core after LOCA - Experimental strategies and test facilities

International Journal for Nuclear Power, Vol. 65 (2020), Issue 6/7, 341-345

U. Harm, H. Kryk, U. Hampel

Electrochemical corrosion studies on zinc in boric acid containing electrolytes

EUROCORR 2020 (EFC Working Party 4, Session: Nuclear Corrosion), 07.-11.09.2020, Virtual Congress

U. Harm, H. Kryk, U. Hampel, A. Seeliger, S. Alt, W. Kästner

Lab Scale Experimental Studies for Modeling Possible Zinc Removal Efforts in LOCA Situations

The 19th International Topical Meeting on Nuclear Reactor Thermal Hydraulics (NURETH-19), 06.-11.03.2022, Brussels, Belgium

U. Harm, H. Kryk, U. Hampel

Flow-dependent zinc corrosion in boric acid containing electrolytes

Materials and Corrosion, Vol. 74, Issue 2 (2023): 277-284