Experimental and theoretical investigation of fluid dynamics and mass transfer in sandwich packings

Motivation:

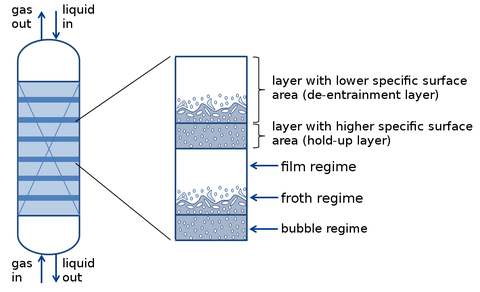

Sandwich packings are a new kind of internals in separation columns. Similar to random or conventional structured packings, they are used to provide a large contact area between the gaseous and the liquid phase. Sandwich packings consist of two layers of corrugated sheet structured packings with different specific surface area which are alternatingly arranged in the column. As a result of this combination, bubbly flow can evolve in the hold-up layer. Compared to conventional packed columns, the interactions between the phases are much higher, especially in the bubbly flow area and the froth regime evolving above. This leads to a higher separation efficiency of the column and therefore to the saving of energy.

Schematic of a column and the flow regimes which occur during the operation with sandwich packings

Objectives:

In the first funding period, a rate-based modeling approach was developed based on the experimental characterization of segment-specific fluid dynamics using fast X-ray tomography and was validated with CO2 absorption measurements.

In the second funding period, the project aim is to further improve the model for application to rectifications and thus finalize the development of the overall model for sandwich packed columns. In this phase of research, the regime-specific dispersion coefficients, liquid phase residence times and liquid-side mass transfer coefficients, the phenomenological description of packing flooding for the correct determination of loading and flooding points and the extension of fluid dynamic correlations to account for changes in material properties will be considered. For the overall evaluation of sandwich packed columns in comparison to conventional packing internals, the finalized model will be used to theoretically investigate both chemical absorption processes and rectification processes.

Methods and results:

The investigations on fluid dynamics of the sandwich and structured packings will be carried out in a column (Ø100 mm) with the B1-Montz reference packings B1-250, B1-250-60, B1-500, B1-750 and B1-1000, which will initially be operated in co-current and counter-current for model material systems. To investigate the influence of the above-mentioned material properties on the hydrodynamic parameters such as pressure loss, bubble layer height, stagnation and flooding points in the impoundment packing column, supplementary measurements to the experiments with air/water (deionized) systems are first carried out. Then glycerine is added at different concentrations to systematically vary the viscosity of the liquid phase. In addition, a Surfynol solution is used to change the surface tension of the liquid phase. Significant changes in the wetting dynamics can be expected with the change in material properties.

In addition, high-precision pressure sensors along the column are used to record axial pressure profiles, which can be used to draw conclusions about the transition regions of the evolving flow configurations. Experience has shown that a large number of measuring points per liquid load is required to precisely determine the loading and flooding point of a sandwich packing.

For the validation of the overall model, further hydrodynamic parameters such as the liquid content and the gas-liquid phase interface are required, which can be taken from the literature or extracted experimentally from reconstructed X-ray cross-sectional images.

Publications:

P. Franke, I. Shabanilemraski, M. Schubert, U. Hampel, E. Kenig

A new approach to model the fluid dynamics in sandwich packings

Chemical Product and Process Modeling, 19, 2 (2023): 211-227