Laserstrahlschweißen mit oszillierendem Strahl

Nahezu simultan zur Einführung der Laserstrahltechnologie in die schweißtechnische Praxis wurde eine Erweiterung des Anwendungsspektrums das Laserstrahlschweißens durch zusätzliche prozesstechnische Maßnahmen angestrebt. Beispiele hierfür sind der Einsatz gepulster Lasersysteme, die Mehrstrahltechnik und die zahlreichen Varianten des Laser-Hybridschweißens.

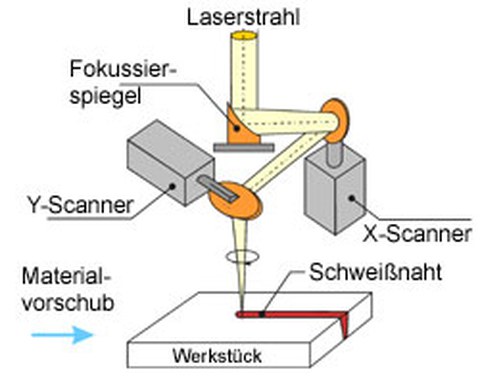

In Ergänzung zu diesen bewährten

Verfahren sind aktuelle Untersuchungen auch auf eine

Prozessmanipulation unter Verwendung optischer Scannersysteme

ausgerichtet. Charakteristisches Merkmal dieser Technologie ist

eine periodische Auslenkung des Strahls über bewegliche

Spiegel, die in den Strahlengang zwischen Laser und Werkstück

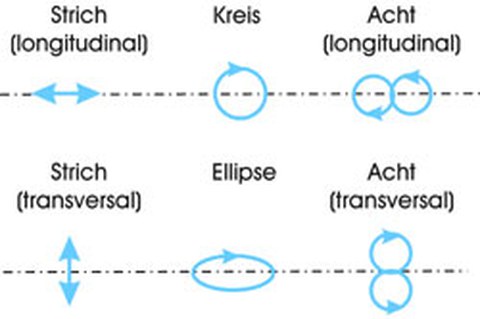

integriert sind (Abb. 1, links). Damit lassen sich verschiedene

Oszillationsformen generieren (Abb. 1, rechts), die wiederum

eine gezielte Einflussnahme auf die Energiedeposition

ermöglichen.

Abbildung 1: Verfahrensprinzip zur Realisierung der Strahloszillation (links) sowie Beispiele möglicher Strahloszillationen (rechts).

Aufgrund der Überlagerung von Vorschub- und

Oszillationsbewegung resultieren komplexe Bedingungen für die

Energiedeposition, wobei die resultierenden Zusammenhänge

zwischen den relevanten Einflussgrößen a priori oder mittels

experimenteller Untersuchungen nicht unmittelbar überschaubar

sind. Daher konzentrieren sich aktuelle Forschungsarbeiten am

LOT auf eine umfassende theoretische Beschreibung dieser

Verfahrensvariante und die Entwicklung entsprechender

Simulationsprogramme [1]. Zusätzlich wird das Potenzial des

Laserstrahlschweißens mit oszillierendem Strahl anhand

praktischer Schweißversuche untersucht und bewertet. Hierbei

stehen insbesondere solche Fügeaufgaben im Vordergrund, deren

Ausführung bei konventioneller Prozessführung problematisch

ist, u.a. das Schweißen verzinkter Bleche im spaltfreien

Überlappstoß, das Hochgeschwindigkeitsschweißen, das Fügen

poren- und rissanfälliger Werkstoffklassen sowie das Schweißen

mit Spalt.

Literatur:

[1] A. Mahrle, E. Beyer (2007), Mathematical

Description of the Transient Energy Deposition in Laser

Materials Processing with Forced Beam Oscillations, 20th

Meeting on Mathematical Modelling of Materials Processing with

Lasers, 17-19/01/2007, Igls/Innsbruck (A).